Tek-Trol Instrumentation in the Dairy Industry

Whether your end product is cream, butter, milk powder, cheese, or simply milk, Tek-Trol offers you unique solutions to help you produce it efficiently, reliably, and cleanly. Tek-Trol products are safe and easy to operate and maintain, ensuring sustained savings and productivity. Where can you use Tek-Trol Instrumentation in the Dairy Industry? Let’s find out!

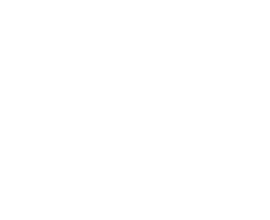

Milk Intake & Storage

Milk is first received in a dump tank from the milk tankers. Then it is usually stored in the tank farm area at approximately 39°F or colder for no more than 48 hours. Afterward, vats and silos in the tank farm are constantly agitated to make sure that the entire volume remains cold, and that the milkfat does not separate from the milk. Whole milk, once approved for use, is pumped into storage silos where it undergoes pasteurization, homogenization, separation, and further processing.

F- Flow Measurement

- Tek-Cor 1100A

- Coriolis Mass Flow Meter

P – Pressure Measurement

- Tek-Bar 3110A

- Explosion-Proof Differential Pressure Transmitter

L – Level Measurement

- Tek-Hydro 4500

- Differential Pressure Level Transmitter

T – Temp. Measurement

- Tek-Temp 2100A

- Explosion-Proof Temperature Transmitter

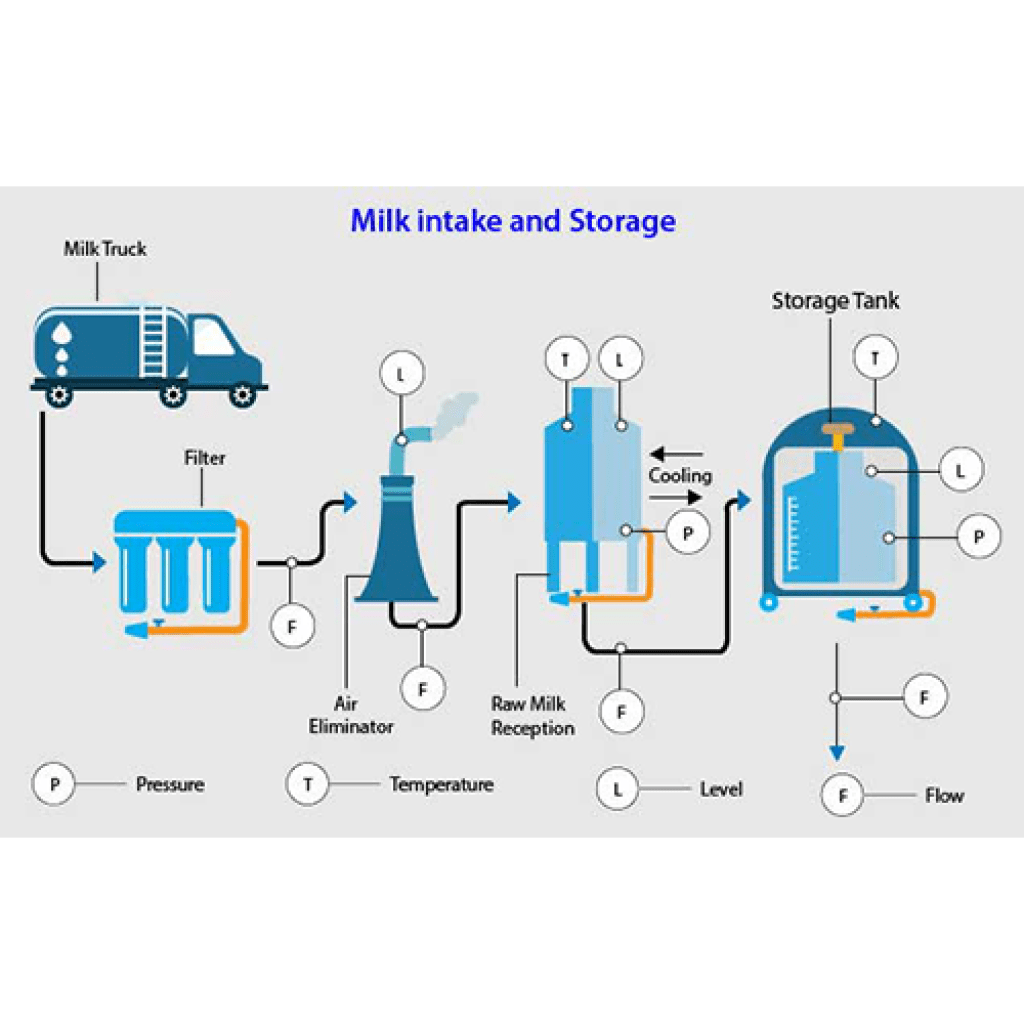

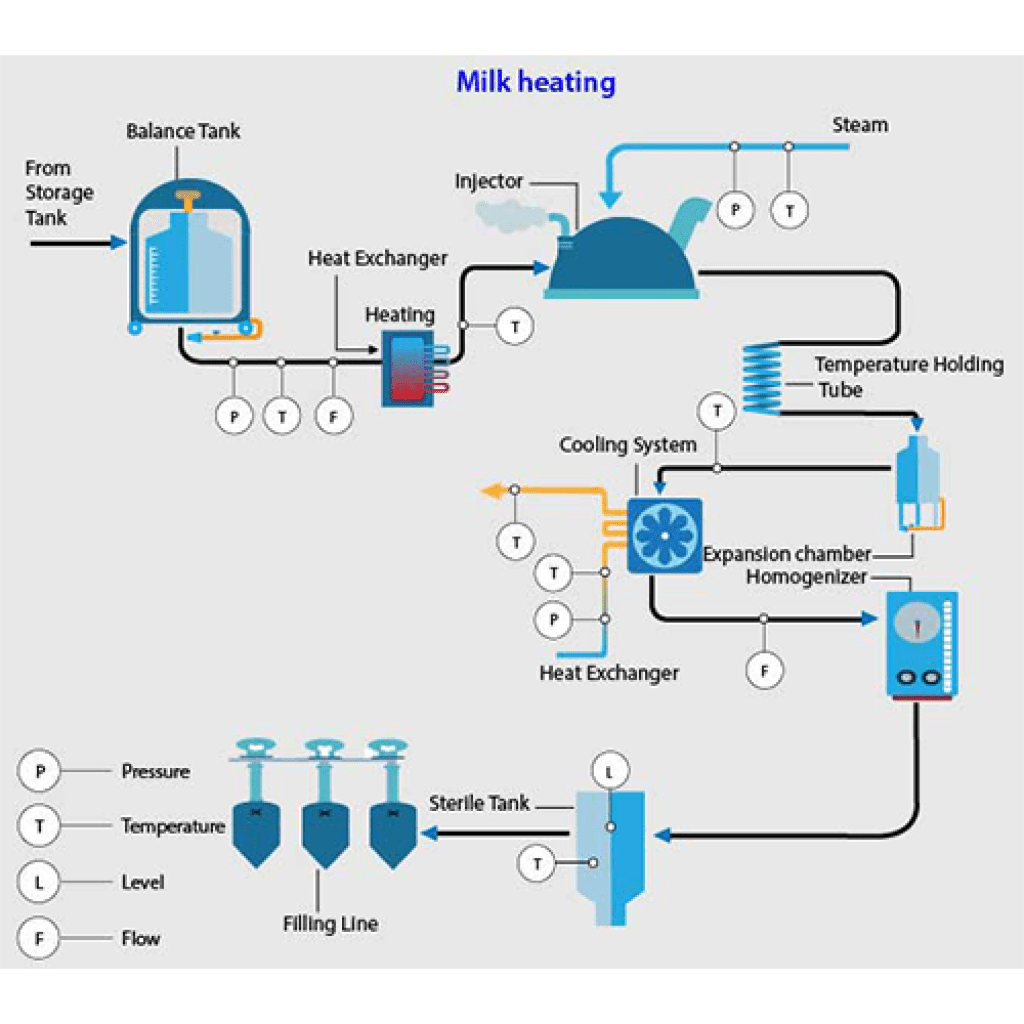

Milk Heating

Pasteurization is the process of milk heating. It is where milk is heated up to 161°F for a predefined holding time. Then the milk is cooled again without allowing re-contamination. The purpose of pasteurization is to kill pathogens and microorganisms that trigger spoilage. Homogenization is a process that involves pushing the raw milk through an atomizer to form tiny particles so that the fat is dispersed evenly throughout the milk.

F- Flow Measurement

- Tek-Flux 1400A

- Electromagnetic Flow Meter

P – Pressure Measurement

- Tek-Bar 3110A

- Explosion-Proof Differential Pressure Transmitter

L – Level Measurement

- Tek-Hydro 4500

- Differential Pressure Level Transmitter

T – Temp. Measurement

- Tek-Temp 2100A

- Explosion-Proof Temperature Transmitter

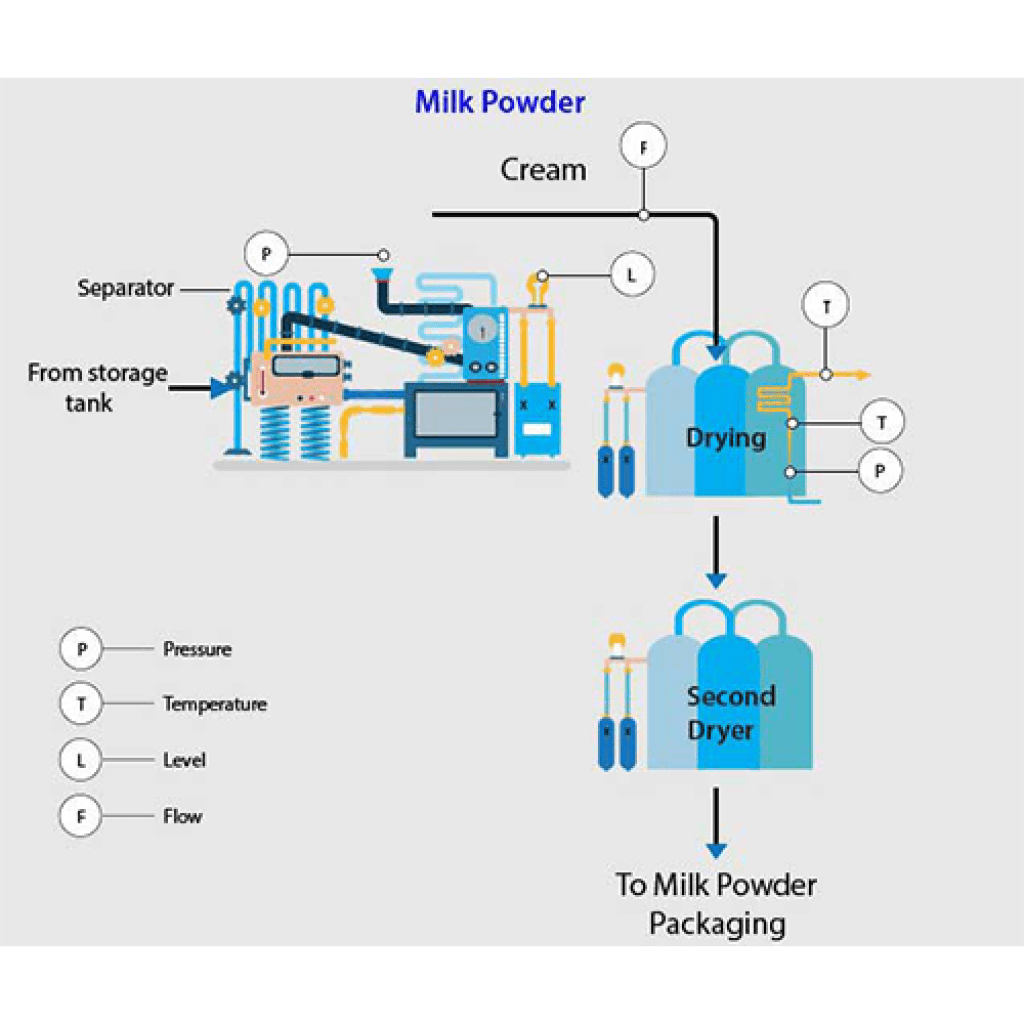

Milk Powder

Milk powder is the process of removing water content by boiling the milk under vacuum conditions or at low pressure and temperature. The resulting concentrated milk is then sprayed into a fine mist of hot air to remove further moisture and is then transformed into powder.

F- Flow Measurement

- Tek-Cor 1100A

- Coriolis Mass Flow Meter

P- Pressure Measurement

- Tek-Bar 3110A

- Explosion-Proof Differential Pressure Transmitter

L – Level Measurement

- Tek-Flex 4100A

- Explosion-Proof Guided Wave Radar Level Transmitter

T – Temp. Measurement

- Tek-Temp 2100A

- Explosion-Proof Temperature Transmitter

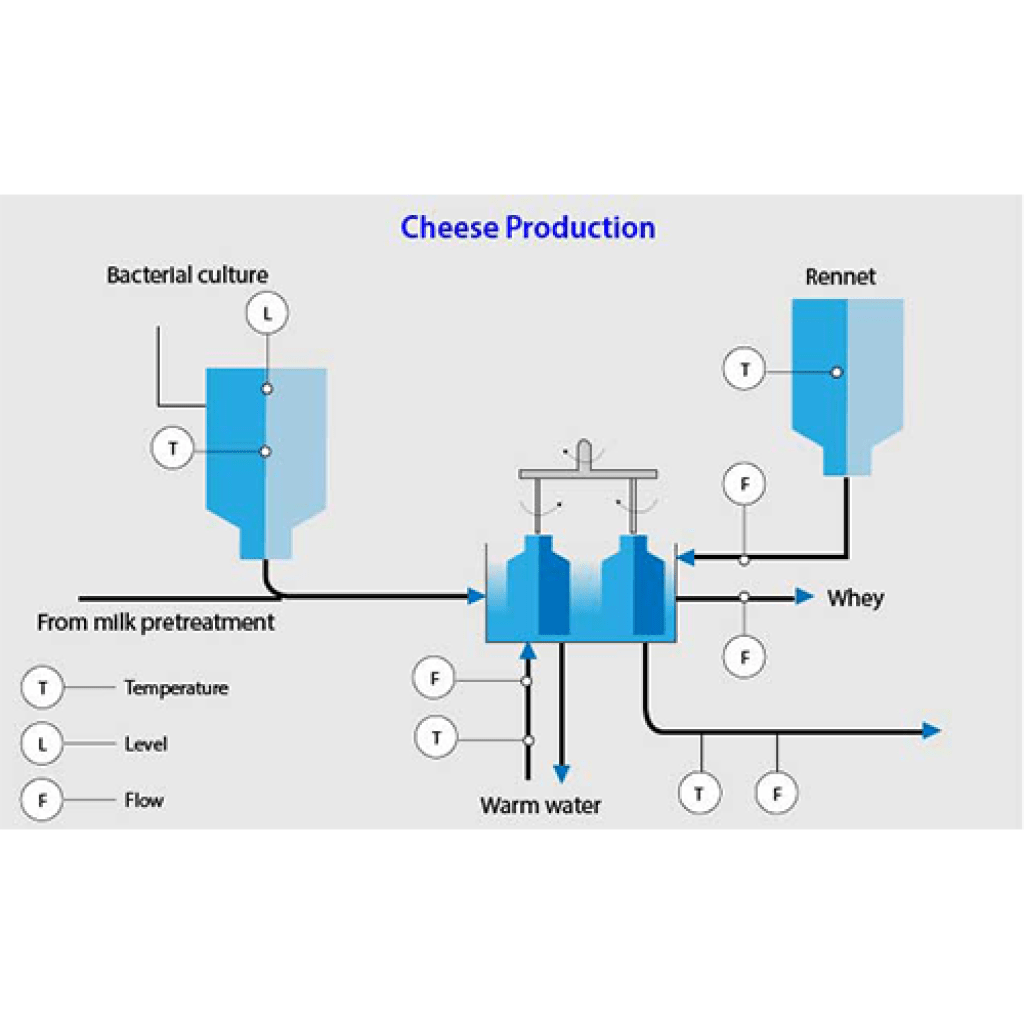

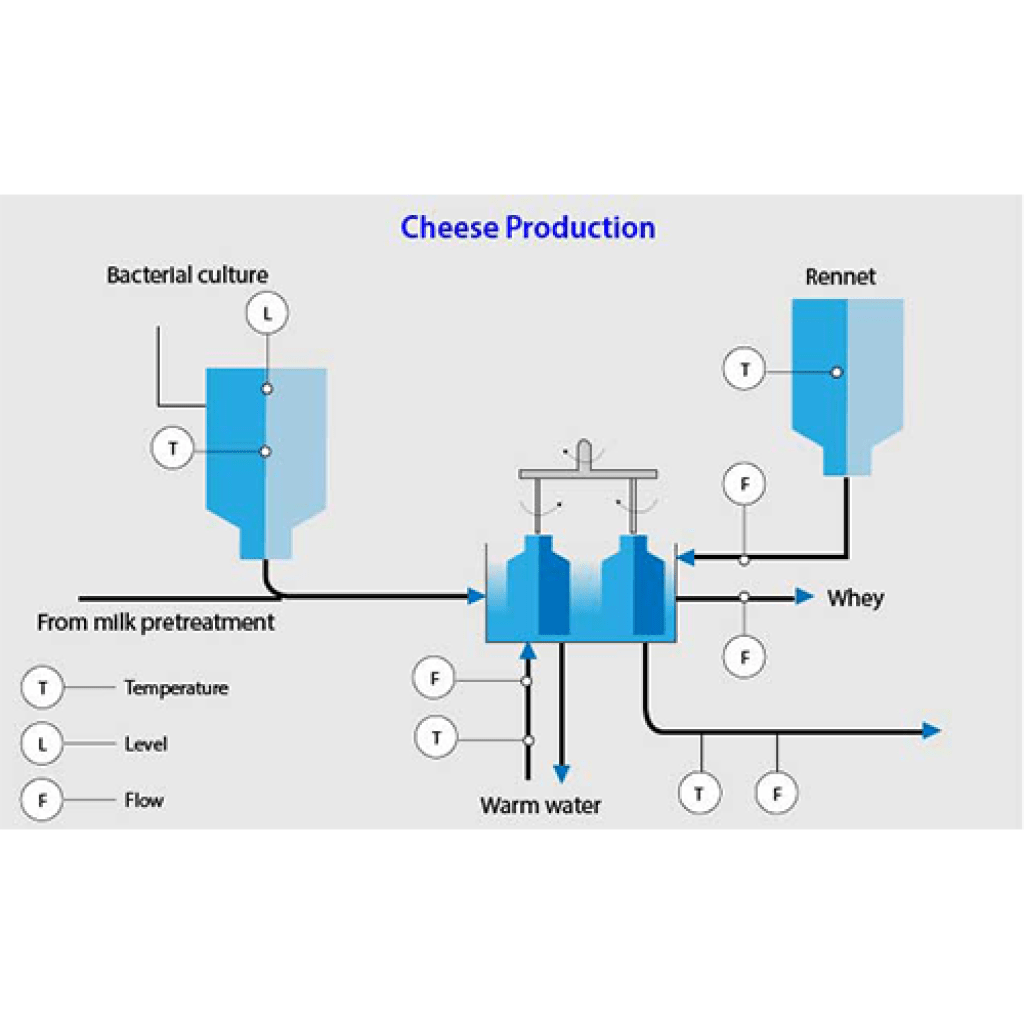

Cheese Production

Starter cultures are added to milk to initiate the cheese making process. They help to determine the flavor and texture of the cheese. Next, rennet, a complex of enzymes, is added to the milk to make the curd. Thirdly the process involves syneresis, that is the release of whey from the curd. Last, curd is distributed, before being pre-pressed into a cheese “cake” and the remaining whey is drained off.

F- Flow Measurement

- Tek-Flux 1400A

- Electromagnetic Flow Meter

T – Temp. Measurement

- Tek-Temp 2100A

- Explosion-Proof Temperature Transmitter

L – Level Measurement

- Tek-Flex 4100A

- Explosion-Proof Guided Wave Radar Level Transmitter

Are you in the dairy industry? Insist on only the best instrumentation in the dairy industry to keep your product safe to consume. Learn more about Tek-Trol products here.

Give us a call today 763-777-9525 to order yours, or fill out the form below for more information.