Apex Industrial Services & Solutions

We are more than just a catalog sales company. Our team is made up of people with many years of experience (over 150+ years) in all the industries we serve. We also heavily invest in training and classes, so our team is always up to date with the newest technology. Seriously, try calling us with a question instead of a part number and you’ll get first-hand experience! Besides offering the products you need from top to bottom, and helping you with your complicated issues, we also provide a variety of services. Watch the video below for more information on Apex Industrial Services & Solutions!

Services Apex Offers:

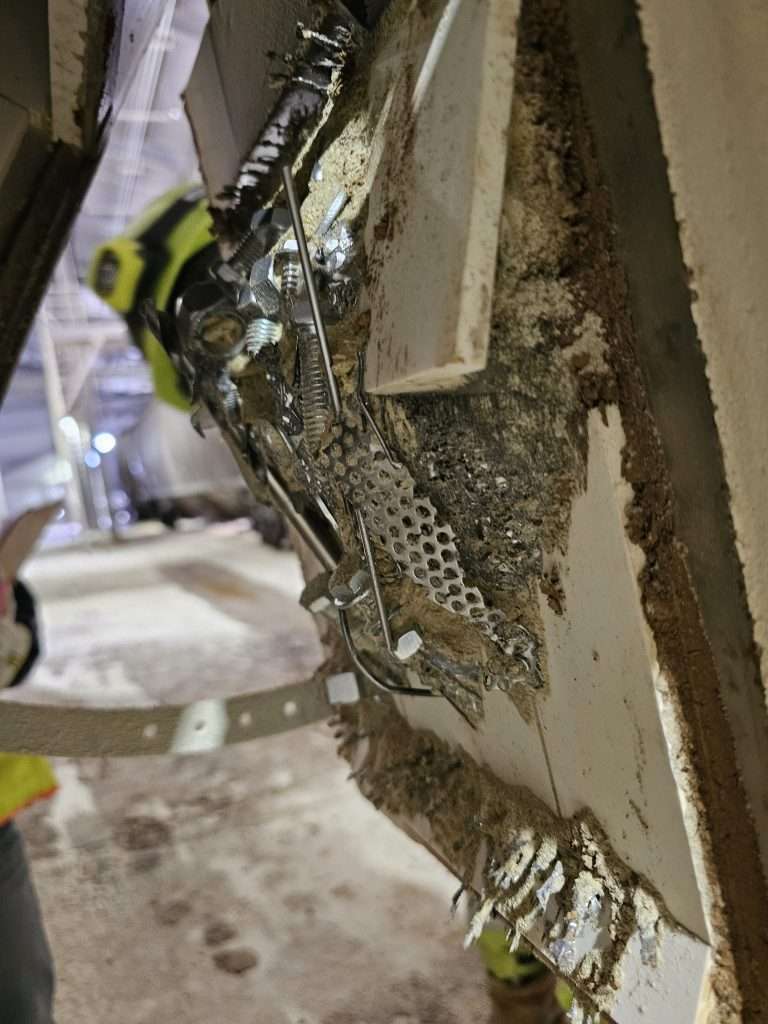

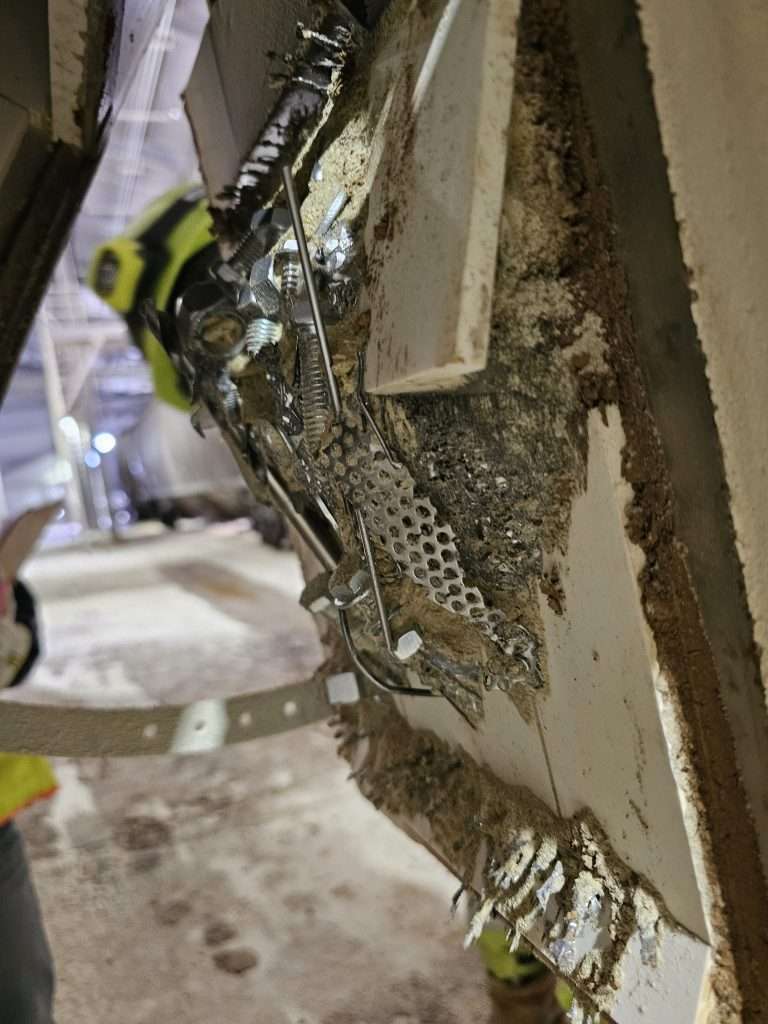

Steam Trap Surveys

Did you know that if your steam traps aren’t working as they should, you can potentially lose thousands of dollars a year just in lost steam?

For Example:

In a plant where the value of steam is $10.00 per thousand pounds ($10.00/1,000lb), an inspection program indicates that a trap on a 150-pound-per-square-inchgauge (psig) steam line is stuck open. The trap orifice is 1/8th inch in diameter.

Estimated steam loss is 75.8 pounds per hour (lb/hr). After the failed trap is repaired, annual savings are:

Annual Savings = 75.8 lb/hr x 8,760 hr/yr x $10.00/1,000 lb = $6,640*

*This example comes form the US Department of Energy January 2012 article “Inspect and Repair Steam Traps” – savings may be even more significant now.

A typical quantity 100 steam trap survey yields around 10 – 20 failed steam traps.

We can audit your steam system and give your plant an accurate report of which steam traps are working properly, and which ones should be replaced.

Magnet Audits

A magnet audit is when a certified technician evaluates, tests, and inspects the performance of your already installed magnets. This includes a full report with information that includes the magnets’ current strength, any required cleaning or maintenance, if the magnet is in the correct location, or if it’s the correct magnet at all.

Many industries, such as food processing, plastics manufacturing, recycling, and mining, benefit by using magnetic separation, metal detection, and material handling equipment. By using magnetic separation technology, metal contaminants are removed from product lines. This creates a safe, high-purity end product for the customer and maintains the integrity of other equipment on the production line. Magnets can and do wear out – so it’s critical that you get your magnets tested to verify they are doing the job you need them to do.

Classes & Training

We currently offer a Steam 101 Training Course. This course covers:

- Sizing and selecting pressure reducing stations

- Sizing and selecting the proper steam trap

- Properly selecting the steam pipe size for the steam load

- Proper control valve selection

- Trouble-shooting steam systems

- Opportunities for energy and maintenance savings

- Steam system and condensate design

- Steam safety do’s and don’ts

Upon completion of this course, you will receive a Completion Certificate showing your achievements. This 6-hour course also includes a light breakfast and full lunch. Classes can be performed at your facility or a nearby facility of your choice. Max capacity is 15 people.

Interested in scheduling your service?

Call us today: 763-777-9525 or email us at Sales@ApexSolutionsMN.com

Or fill out the form below!