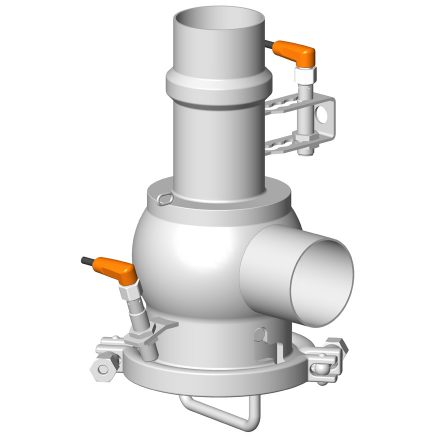

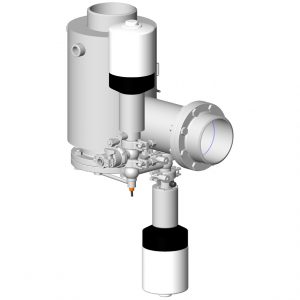

Description

Starmotion Pigging System Application Features:

From DN 25 to DN 150

- SMS, DIN or US versions

Respectful solution of the manufactured product

- Adapted to fluids more or less viscous

Elastomer sealing

- EPDM or FKM

- Adapted to fluid with particles

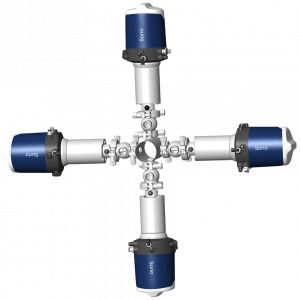

2 stations, 3 configurations

- Automatic in-line cleaning with 1 stop station and 1 in-line cleaning station

- Automatic in-line cleaning with 2 in-line cleaning stations

- Manual offline cleaning with 2 stop stations

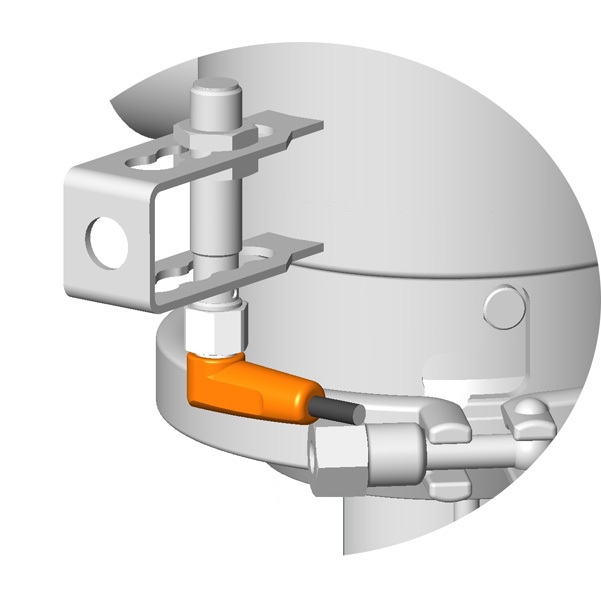

Secured solution

- Bayonet coupling securing the disassembly

- Fixing clamp collar with safety sensors informing of the pig presence

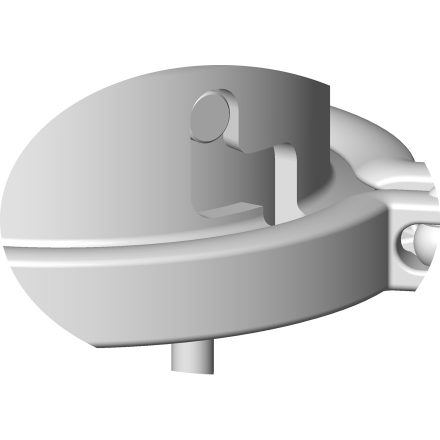

Lip reversal system, as standard

- Facilitating the pig movement

- Limiting pig wear

Signal and control

- From Sorio control top fitted onto push and blocking actuator

- Pigging mode available in IO-Link version

Connections

- Aseptic screw connection DIN 11864-1

- Aseptic flange connection DIN 11864-2

- Aseptic clamp connection DIN 11864-3