Description

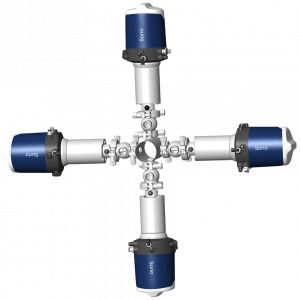

Starmanifold Starwheel Injection System Application Features:

DN 2″, 2.5″, 3″ or 4″, for the main Stream

- Injection points: DN 20, 17, 13, 10, 7, 5, 3

Easy assembly and disassembly

- Injection valves connected to the main pipeline thanks to clamp connections

Options

- Set of injection quills

PEEK or PFA plug

Various material for many applications

- EPDM, FKM, FFKM or VMQ seals

- Stainless steel 316L 1.4404

- On request, 254 SMO, AL-6XN, Uranus B6, Hastelloy C22, 904L

Variants for injection solutions

- From a piggable VEOX mix-proof valve, multi-size bodied version

- From a compact manifold of 3 valves, connected to the main pipeline

Precise injection with Starwheel solution

- Interchangeability of the injection valves

- Many injection points

- Circulation loop of injected product from DCX4 fractional divert valve

Starmanifold

- Injection from the main pipeline wall

- Non interchangeable injection points