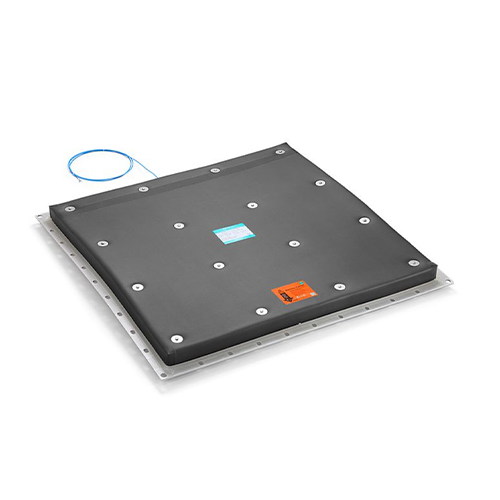

Description

Mechanism

When pressure rises, the EGV explosion vent opens at the defined breaking point and releases pressure out of the vessel into the surrounding area.

Applications + Industries

- Aspiration plants

- Breweries

- Elevators

- Filters

- Conveyors

- Wood processing

- Food production

- Mixers

- Mills and grinding plants

- Recycling

- Screens

- Silos

- Destoners

- Spray dryers

- Animal feed production

Advantages

- High venting capacity and full bore opening due to low surface weight

- High stability and opening speed through integrated bionic structure

- Direct installation of the explosion vent even on round vessels prevents bacteria formation. No complicated flange constructions required

- Adapts perfectly to your process due to the wide range of EGV geometries available

- Quick and easy installation while torque is independent. No additional counter frame required

- Significant space savings due to the integrated gasket and frame in the explosion vent.