Pros and Cons: The Difference Between Plate and Frame and Shell and Tube Heat Exchangers

Heat exchangers are utilized in nearly every large industrial plant. They are used to heat and cool fluids using unique processes and are chosen based on the needs of the specific plant. There are many different types of heat exchangers, and each is typically customized to meet the needs of each application. Two of the most popular types of heat exchangers are the Plate & Frame and the Shell & Tube models. But what is the difference between plate and frame and shell and tube heat exchangers, and which is right for you?

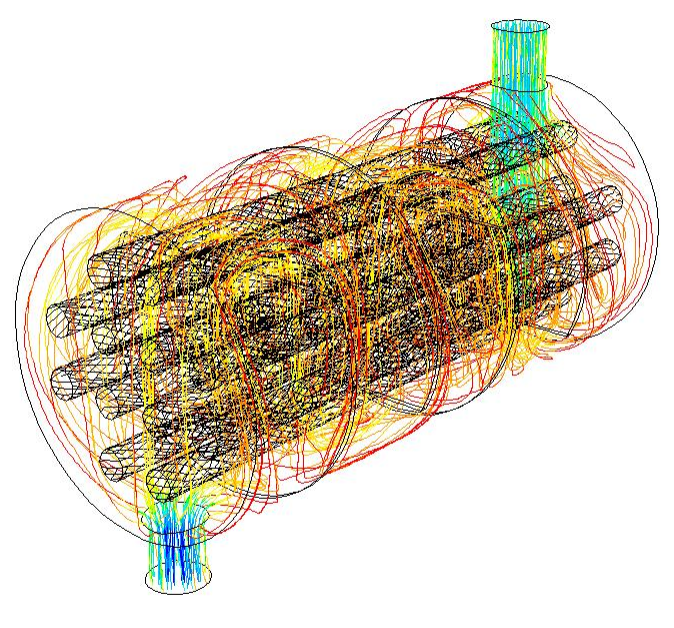

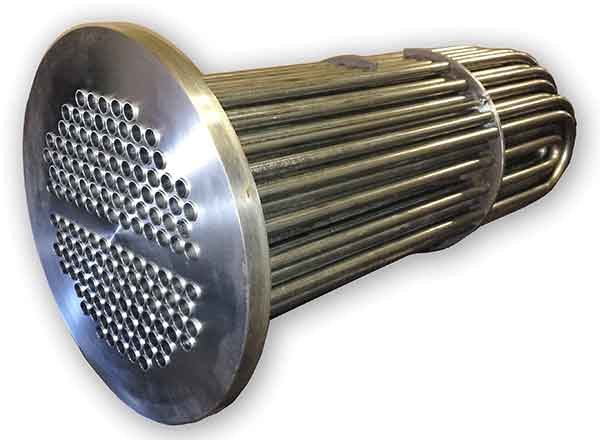

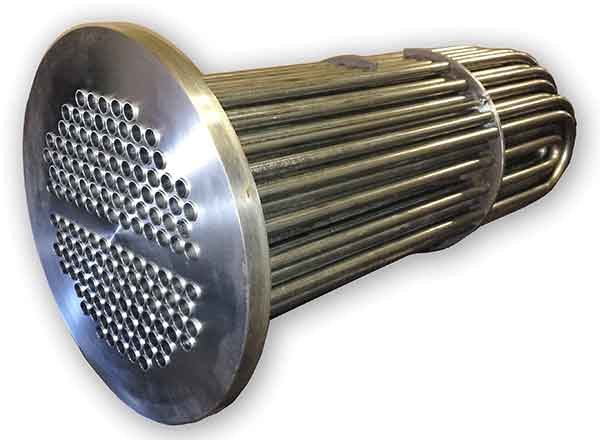

Shell and Tube

The shell and tube heat exchanger are exactly what it sounds like: a bundle of tubes inside of a large pressure vessel shell. It works by having one fluid running through the tubes and another fluid of a different temperature running through the shell. Heat is transferred between the two and is used to efficiently heat or cool liquids.

Typical Applications: Oil Refineries, Large Chemical Processing, Power Plants, Liquid-Cooled Chillers

Ideal For: Medium and High-Pressure Media

Media: Liquid (Including Gases)

Advantages:

- Easy to Service

- Tubes can be Customized for Specific Media

- Can Withstand High Pressures and Temperatures

- Inexpensive Compared to Plate and Frame

- Less Pressure Drop

- Easily Detect and Isolate Leaks

- Can Take up a lot of Real Estate

- Fouling can Occur with Certain Media

- Less Efficient than Plate and Frame

- Cooling Capacity Cannot be Altered

- Can be Difficult to Find Replacement Parts and Tubes

Brands We Carry: WCR, Marlo, CBW, Enerquip

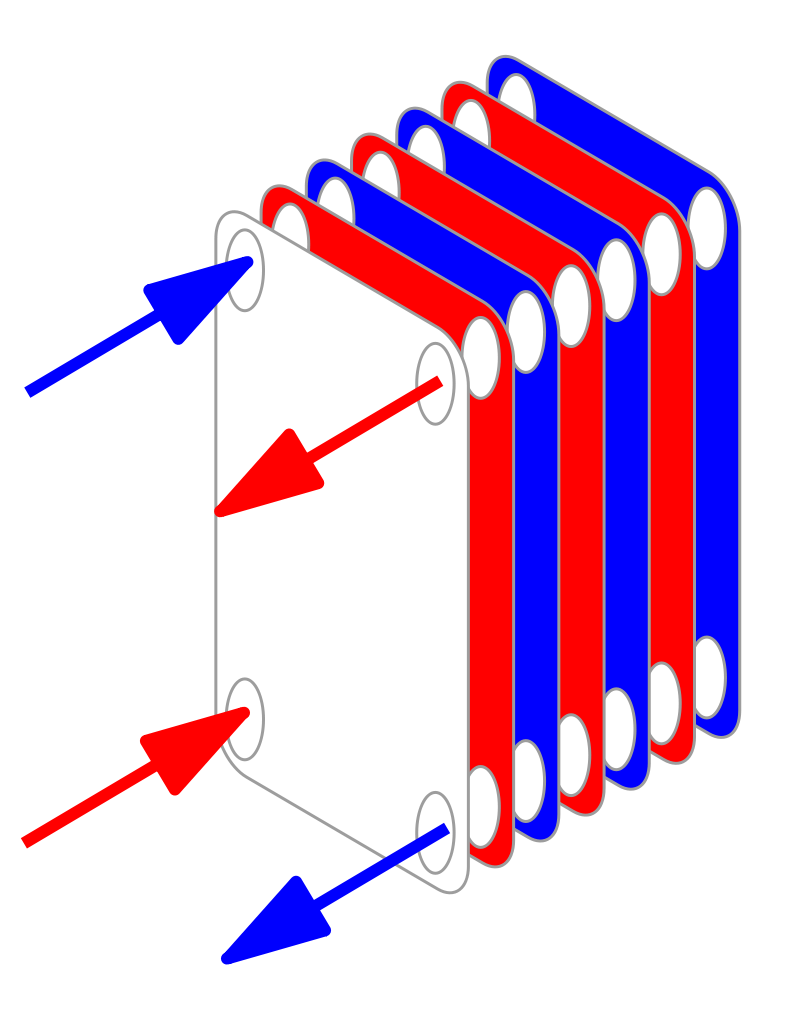

Plate and Frame

Not surprisingly, the plate and frame heat exchanger are exactly what they sound like as well. They are made up of many thin metal plates that are secured in a frame and transfer heat between two liquids. Different models are available depending on your needs.

Typical Applications: HVAC, Food and Beverage Industry, Pharmaceutical Industry

Ideal For: Medium and Low Pressure and Temperature Media

Media: Liquid (Including Gases)

Advantages:

- Greatly Increases Speed of Temperature Change due to Large Surface Area

- Can Withstand High Temperatures

- Corrosion Resistance Standard

- Easily Replace or Clean Plates and Gaskets

- Compact Design

- Widely Used – Parts and Equipment are Easily Obtained

- High Pressure Drops

- Higher Cost for Pumping

- Doesn’t Work Well with Large Temperature Differences

- Moderate Leakage Risk

- Likely Fouling to Occur

Brands We Carry: WCR, Delta T, Gestra

Most issues that occur with heat exchangers are due to incorrect type, size, location, and materials. Still unsure of the difference between plate and frame and shell and tube heat exchangers? Give us a call and our team will do the work for you.