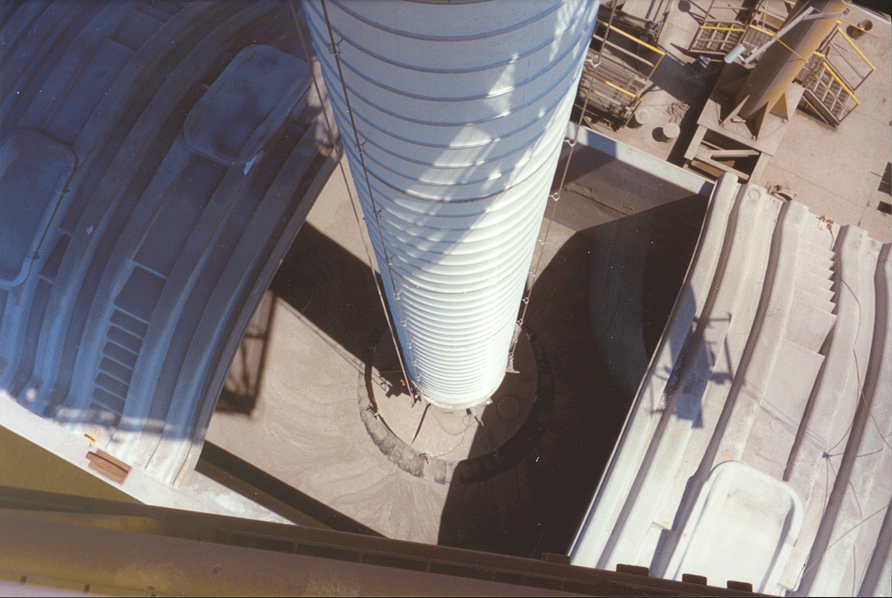

Heat Exchanger Servicing and More

You rely on heat exchangers. If your heat exchanger goes down, then your business comes to a halt. That’s why Apex has partnered with WCR. WCR has a massive network of service professionals that are ready to spring into action across the nation. WCR has over 20 field service teams across 9 service centers in North America. Annually they service over 500,000 heat exchanger plates! Learn more about the heat exchanger servicing that WCR has to offer.

Heat Exchanger Cleaning

Not all cleaning is equal. WCR has invented the cleaning process that has been imitated by other companies for years – even OEMs. They pride themselves in selecting specific methods for your application to get the best clean. The typical process includes:

- Pre-cleaning: Includes high pressure waster cleaning and brushed hand-scrub to remove loose scaling and fouling.

- Power-Blasting: Removal of rigid scaling not dissolved in acidic or caustic solutions.

- Chemical Bath: A carefully selected process of altering chemicals, temperatures, and agitation for the most effective cleaning process.

Dye Penetrant Testing

Dye testing is the process for locating cracks, pinholes, or failures in your heat exchanger plates. This process allows WCR to detect even miniscule imperfections. 100% of the plates in your heat exchangers are dye tested to eliminate all bad plates. Early discovery of plate defects alleviates cross-contamination concerns. This saves you costly downtime in the future. Here’s how it works:

- Plates are cleaned to WCR standards.

- The penetrant is applied to one side of the plate.

- A developer is then applied to the opposite side of the plate.

- The plate is inspected – if any penetrant is detected by the developer, then the plate is deemed failed. Remaining plates are cleaned and returned. Failed plates are replaced.

Ultraviolet testing and vacuum testing are available by request. Ultraviolet testing is used when fluid mediums can only be detected under UV light. Vacuum testing is used for welded and semi-welded heat exchanger plates.

Full Service Regasketing

The regasketing service is specialized for each model, gasket type, and bonding agent. A rigorous process is followed before and after the gasket is applied to ensure proper adhesion, alignment, and function. This is what to expect:

- Inspection: Trained experts inspect every piece of equipment and log each plate and component for full transparency.

- Cleaning & Gasket Removal: Plates are cleaned, and all glue is removed with a specialized cleansing process. Gasket grooves are prepped for proper sealing.

- Dye Test: See above for more information on the Dye Penetrant Test

- Gasket Application: Gaskets are selected based on your application, temperature, and pressure – maximizing longevity. Gaskets are applied by a professional.

- Compression & Oven Curing: Gaskets are compressed into the plate groove by specific tightening dimensions. All glued gaskets are heat cured under pressure providing you with 10x the lifespan of uncured rubber glued gaskets.

- Inspection & Hydro-Test: Every plate is inspected for gasket straightness, solid bonding, excess adhesives, and deformations. Plate packs sent along with frames are hydrotested to simulate operating levels of application. Failed plates will be replaced.

The WCR service crews across the United States are strategically located to reach any destination within 8 hours. Most of the services are performed on-site to minimize downtime. Labor and parts are under warranty for one year after services are completed. Are you interested in learning more about heat exchanger servicing? Call Apex or fill out the form below – our team will arrange everything for you and make the process as streamlined as possible. 763-777-9525