Description

ProMet provides a flexible platform for all your metering supervisory needs and includes many standard features.

- System architecture graphical mimic.

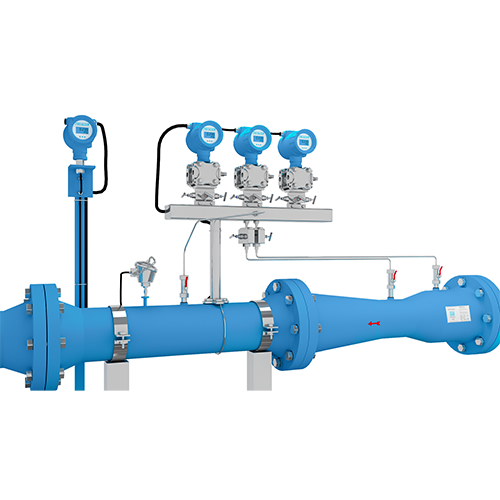

- Metering skid graphical mimic.

- Legend key for all mimics.

- Automated and on-demand reporting.

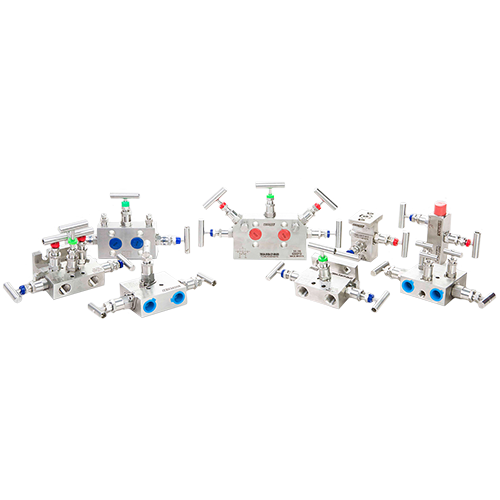

- Dual instrumentation comparison.

- Current alarm summary and filtering.

- Alarm and event historian.

- Easy interfacing with external systems Flow.

- Computer web-browsing built in.

- Historical trending.

- Report archiving and recall.

- Remote access.

- Document Manager.

- Instrument Management.

- A single high-level interactive map showing the health of the systems.

- Bespoke rules determine the health conditions.

Communications

- Modbus, DNP3.

- OPC DA interfaces.

- Obtain metering data.

- From flow computers, MSC, SCA DAsystems, DCS, Plant Historians.

- Gateway located at remote sites.

- Obtain metering data from various sources.

- Securely and efficiently transmit it to the server.

- Email.

- SMS notification of specific status conditions.