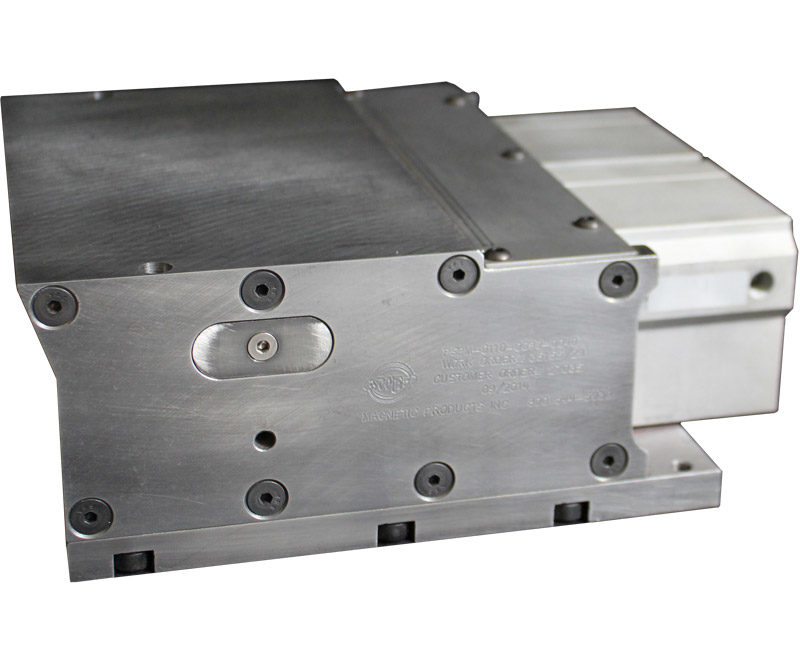

Description

How the Pneumatic Switchable Permanent Magnet Works:

While electromagnets need continuous and expensive electrical power to maintain magnetism, MPI’s Pneumatic Switchable Permanent Magnet requires electricity only to turn it on and off. This benefit is two-fold.

- Less electrical power means lower utility costs.

- The elimination of continuous electrical power. This means the Magnet is safer to operate than an electromagnet.

Should power be interrupted, the Magnet retains its magnetism and continues to hold the workpiece without the need for an expensive battery back-up system. In comparison, an electromagnet that losses power will immediately release the workpiece. This causes it to send it off the machine tool and creating a significant operator safety issue. You can rest assured that this unit will hold your workpiece in place reliably as intended.