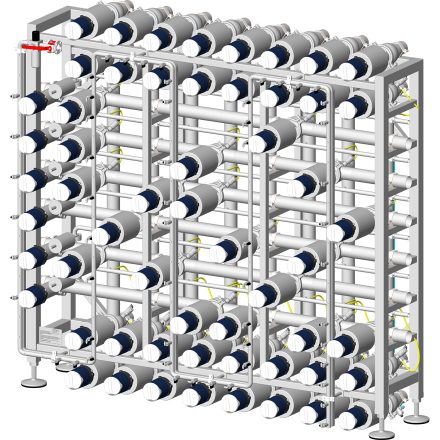

Description

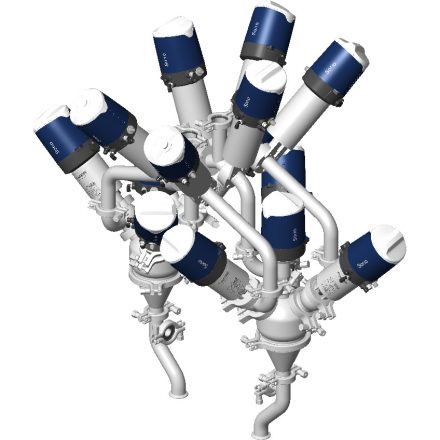

Manifold or Valve Fitting Assemblies Application Features:

From DN 10 to DN 250, from small to complex module

- Adapted to all process configurations

- No limit of valves

Numerous functions

- Distribution

- Receiving

- Drawing off

- Injecting

- Cleaning and sterilization of process lines

CO2 control

- Vertical manifold “gasblock”

- CO2 recovering and distribution in storage tank of beer

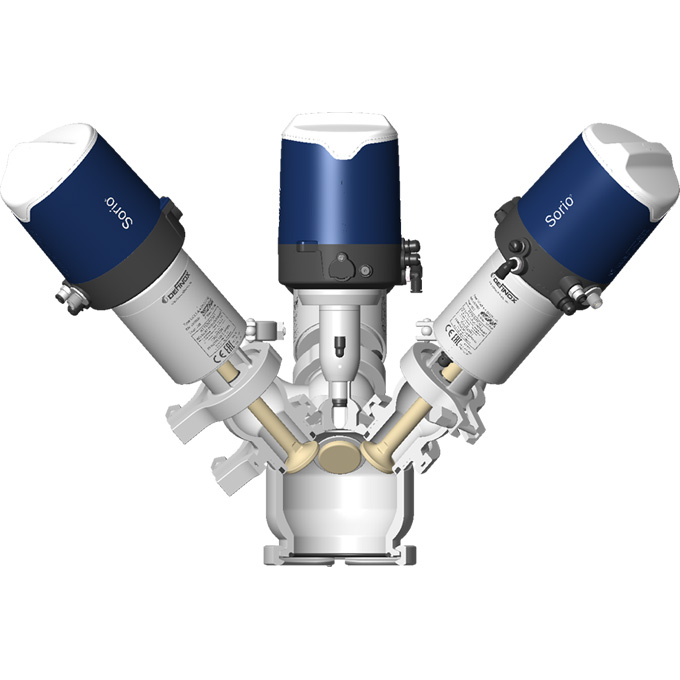

Ultra-compact version

- 3 inlets

- 1 outlet

- Gravity flow of the fluid

- Chipping on the main pipe

- No retention zone

Many materials for numerous applications

- Stainless steel 1.4404 / 316L, as standard

- 254 SMO, AL 6XN, Uranus B6, Hastelloy C22, 904L

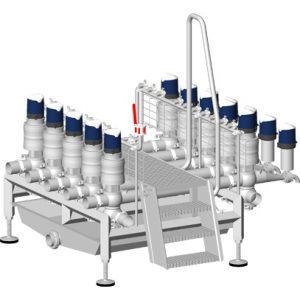

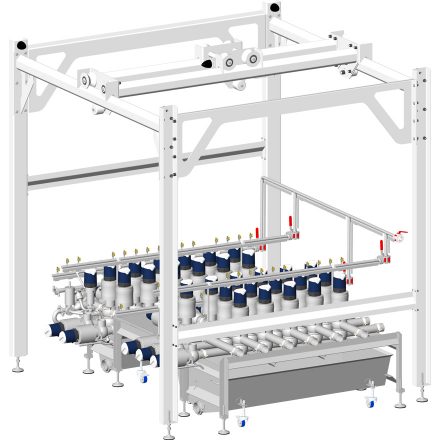

Customization with no limit

- Lifting hook

- Frame with adjustable feet

- Gateway and ladder facilitating the maintenance

- Removable drop drip tray

Signal and control of the valves

- From Sorio control top, available in Digital, AS-i and IO-Link versions.

- Addressing of the valves

Many materials for numerous applications

- Stainless steel 1.4404 / 316L, as standard

- 254 SMO, AL 6XN, Uranus B6, Hastelloy C22, 904L