Description

Applications + Industries

- Aspiration Plants

- Breweries

- Elevators

- Filters

- Conveyors

- Wood Processing

- Food Production

- Mixers

- Mills and Grinding Plants

- Recycling

- Screens

- Silos

- Destoners

- Spray Dryers

- Animal Feed Production

Mechanism

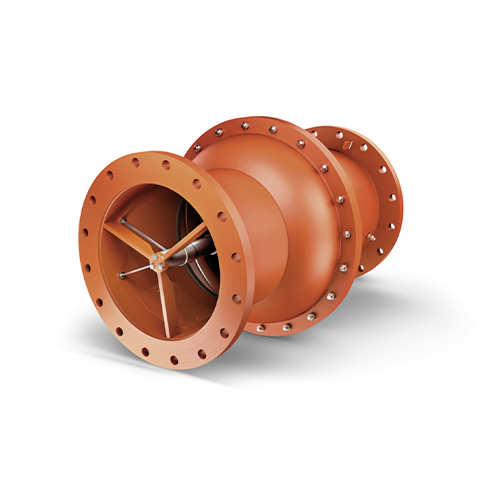

In the event of an explosion, the EXKOP® controller receives a trigger signal (e.g. from the signaling unit of the Q-Rohr® or an explosion vent, from a pressure switch or spark detector) and activates the connected EXKOP® quench valves. These close within a few milliseconds and thus protect adjacent plant components. After being triggered, the quench valves can be put back in operation once again at the touch of a button.

Advantages

- Effective protection through high-speed detection of explosion events.

- Returns to operation again immediately after triggering.

- Self-monitoring safety electronics with operating data storage.

- Modem-compatible system analysis allows for remote maintenance (optional).

- Instant status forwarding to customer PLC (Alarm, failure, maintenance, etc.).

- Processes wide range of trigger signals for easy retrofitting to existing plants.

- Fail Safe mechanism automatically closes the valve if the power/compressed air fails or the valve is manipulated.

- Reliable, process-optimized protection against explosions in adjacent plant components.

- Avoid downtime after the mechanism is triggered.