Description

How Eddy Current Works:

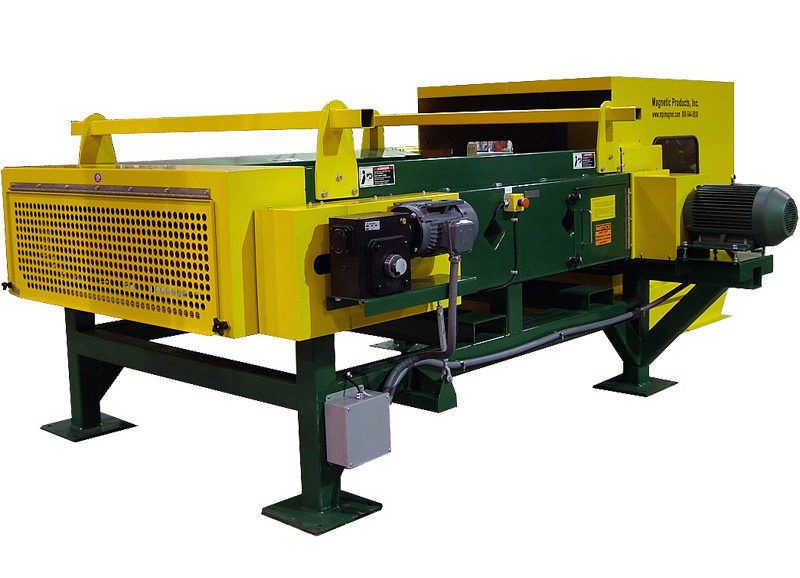

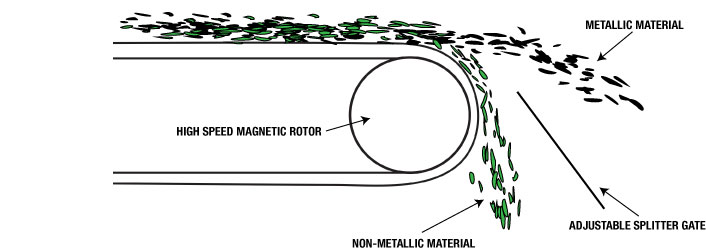

Material is fed onto the conveyor belt of the eddy current separator. The material is conveyed over a spinning magnetic rotor where separation occurs. The two streams of material discharge over and away from the separator.

The main component of MPI’s Eddy Current Separator is the magnetic rotor which uses a series of permanent Rare Earth magnets mounted to a plate. These are attached to the motor driven shaft. These magnets are covered by a fiberglass shell with ceramic tiles that reduce wear and allow the conveyor belt to ride over them.

The magnetic rotor spins independently and at a much faster rate than the conveyor belt pulley. When product such as aluminum passes over the shell, the spinning magnets inside the shell generate an eddy current in the aluminum. This creates a magnetic field around the piece of aluminum.

The polarity of the magnetic field of the aluminum is the same as the rotating magnets, which causes:

- The aluminum to be repelled away from the separator beyond the product flow trajectory

- Separation of the aluminum from the rest of the product being conveyed. Product such as plastic, glass or other process materials simply fall off the end of the separator