Description

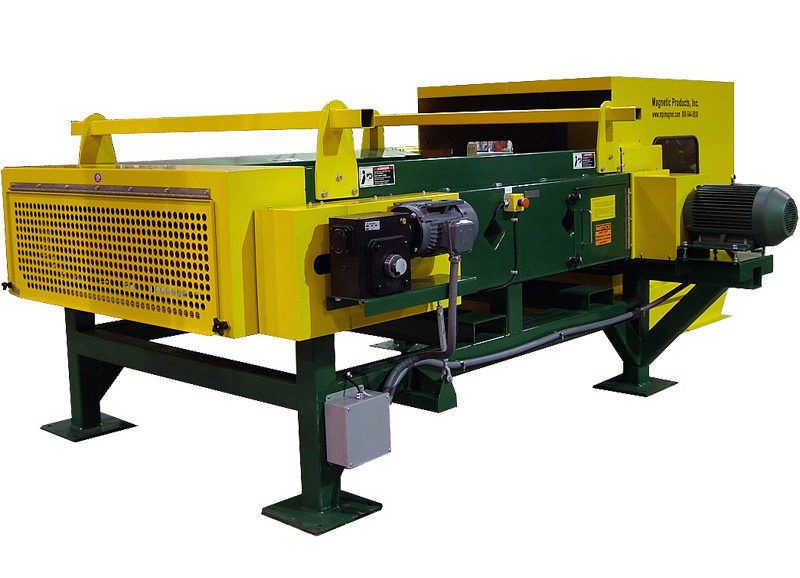

How Commingled Sorting System Works:

Mixed product containing ferrous metal is fed into a hopper. A vibratory conveyor then evenly distributes the product on to the main conveyor belt. Mounted above the main conveyor belt is a magnetic rail with another conveyor belt moving over its working surface. The magnetic rail, which is the length of the main conveyor moves across belt edge to belt edge. While the magnet is moving back and forth, captured tramp metal is agitated, releasing entrapped non-ferrous material. The ferrous metal travels the down the belt until it is released in a separate collection bin from the non-ferrous metal. For increased magnetic separation, including some grades and types of stainless steel, a magnetic head pulley using MPI’s Arch Technology can be installed at the discharge of the non-ferrous conveyor.

Options:

- Carbon steel painted finish

- Stainless steel painted finish

- MPI offers a variety of eddy current separators, conveyors, feeders, and magnetic separators- contact our Customer Service Department to plan your turn-key system today