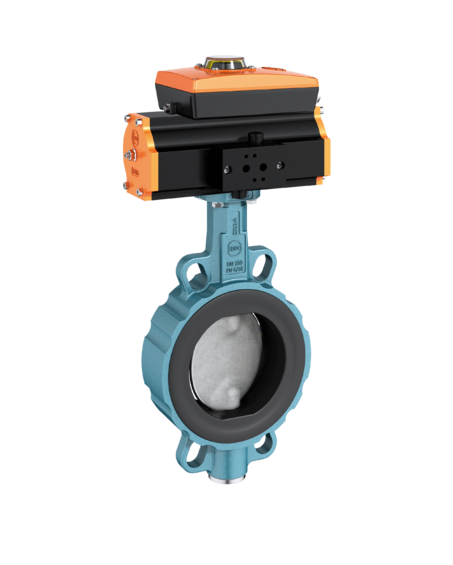

AWWA Butterfly Valve

- Ductile Iron ASTM A-126 Class B which conforms to AWWA C504 relative to lengths, minimum body shell thickness. End connections are 150# flanged connections per our drawings.

- Cast Iron ASTM A-126 Class B (3”-20”) or ASTM A-48 class 40 (24”). Discs are furnished with 316 Stainless Steel a seating edge to mate with rubber seat of the body.

- Buna N rubber, located on the valve body (seat-in body). Sizes 20” and smaller have bonded seats which meet the test procedures of ASTM D-429 Method B.

- ASTM A-276 Type 304 Stainless Steel. Elite Valve shaft seals are designed with standard self-adjusting with Chevron V-type packing. Shaft seals are designed to allow replacement without removal of valve shaft.

- Sleeve type design, corrosion resistant and self-lubricating. Our bearing loads do not exceed 1/5th of the compressive load strength of the material.

- Fully grease packed, with stops in the open/close position. Actuators can withstand an input torque of 450ft./lbs against each stop. The traveling nut does not engage alignment grooves in the housing.

- Elite Valve provides our valves as a standard with POWER COATED EPOXY finish (Fusion bonded), to provide the best resistance against exterior corrosion, to provide years of maintenance free life, etc.

- The AWWA series butterfly is manufactured with a solid 316 Stainless Steel edge design, which is machined to provide optimum performance and sealing.

- Elite Valve AWWA series butterfly valve, 3”-20” utilizes the fully lined seat body technology per AWWA 504 Standard. The standard EPDM seat is bonded to the body, per ASTM D429, optional seats are available to suit specific applications, including Viton, and Buna “N”. The smooth finish reduces the chance of mineral and scale build up, which can affect flow performance.

- Every valve manufactured by Elite Valve is hydro-statically tested for seat leakage and performance per AWWA 504 Standard prior to shipping. The valve seating are inspected, torque adjustment made, travel stop inspected and adjusted to provide years of reliable performance.