Description

Specific Pigging System Application Features:

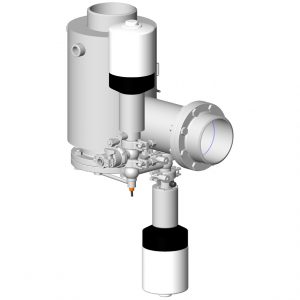

Double walled configuration

- Maintaining the process fluid at a temperature (cold or hot)

Numerous material for many applications

- 254 SMO

- AL-6XN

- Uranus B6

- Hastelloy C22

- 904L

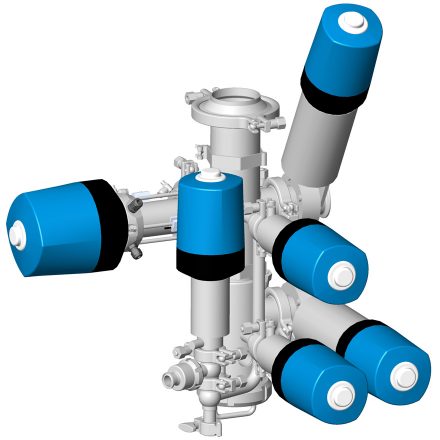

Double pigging configuration

- Ensuring the distribution of a process fluid to several points

- Guaranteeing a physical barrier between two different fluids

- Allowing better management of process fluid changes in line

Elastomer sealing

- EPDM, FKM, FFKM

- Adapted to process fluids with particles

Explosive atmosphere

- In-line cleaning and stop stations available in ATEX version

3A stations

- Meeting 3A regulation