Description

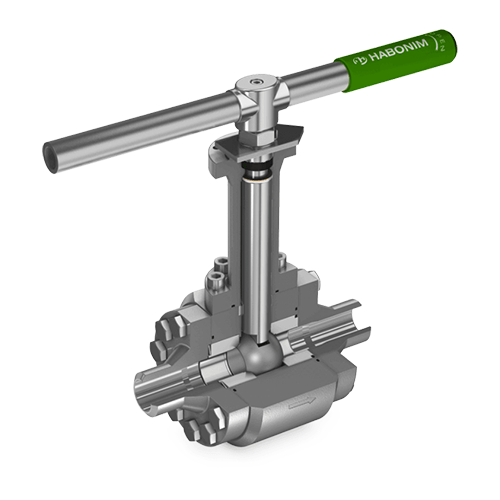

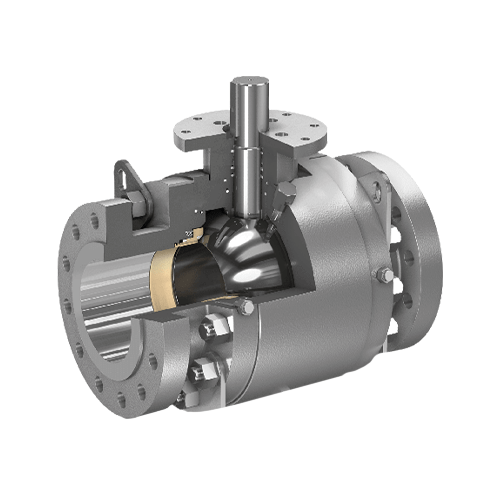

Size Range: 1/4″ to 8″ (DN8 – DN200)

Pressure Range: Class 600

Temperature Ratings: -76°F to 1,200°F

Design Features

- -60°C to 650°C (-76°F to 1200°F) only with body & ends material code H/J V-ball or Shaped seat (V or slot) for control applications

- Standard or full port design

- Forged or cast

- ANSI B16.34 Class 900 (wall thickness)

- Size ¼”-2” (DN8-DN50)

- ANSI B16.34 Class 400 (wall thickness)

- Size 2 ½”-6” (DN65-DN150)