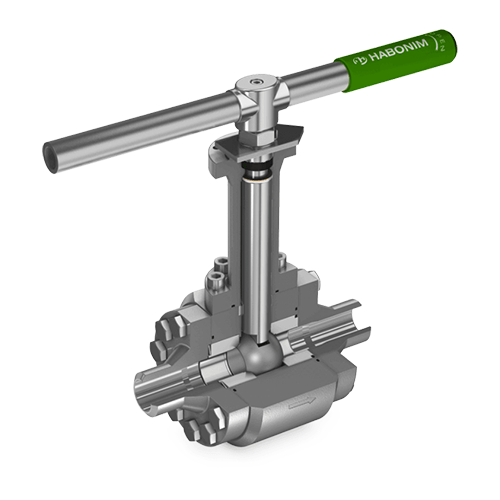

Description

Size Range: 1/4″ to 6″ (DN8 – DN150)

Pressure Range: Class 2500

Temperature Ratings: Up to 1,200°F

Design Features

- High Pressure

- High Temperature

- Class 2500

- Full differential pressure for sizes up to and including 2″ (DN50)

- Differential pressure of up to 255 bar (3700 psi) for sizes 2½” (DN65) and above with hybrid seats

- Pressure containing parts are in compliance with ASME B16.34 for wall thickness

- Design type-tested for burst testing of four times the pressure rating for 5 minutes

- A one-size-up stem made of high tensile material complies with ASME B16.34 and API 6D

- For drive train requirements provides a sufficient safety factor during operation.

- A special hybrid seat design is comprised of a metal housing and polymer insert machined as a single unit

- Provides bubble tight shut-off (Rate A) combined with lower operating torque