Description

- Flush in the T slot, no protruding structures

- With safecoated connector

- PTFE protective tube to prevent damage by weld splatter

- Easy fit ‘drop from the top’ into a slot

- Very short length for different cylinder profiles

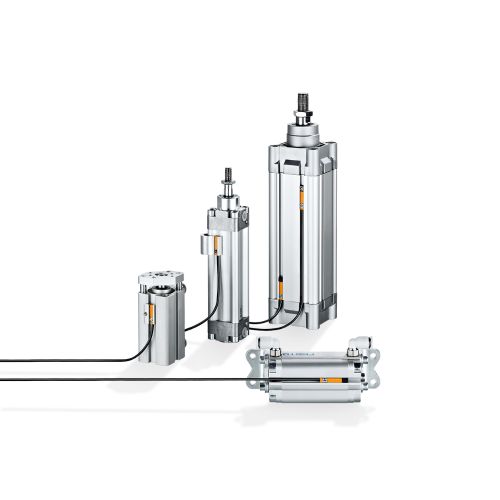

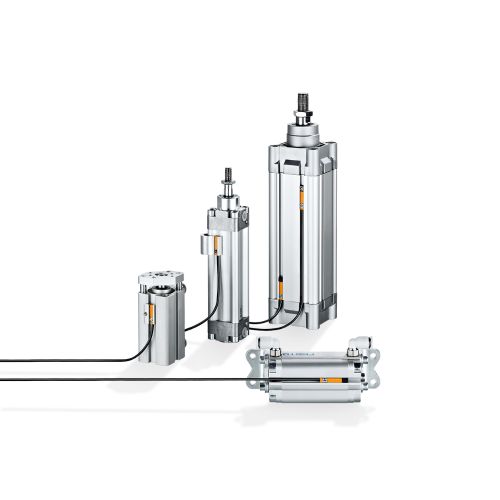

Cylinder sensors are used for position detection of pistons in pneumatic cylinders. They are directly mounted onto the cylinder. The ring magnet attached to the piston is sensed through the housing wall of non-magnetisable material (e.g. aluminium, brass or stainless steel).

The electromagnetic field immune cylinder sensor detects the alternating field of the weld current and holds the output signal during this time, independently of the welding time. Then the sensor resumes normal switching operation (piston or no piston).

Thanks to the wide selection of optional adapters the cylinder sensor can be fixed to almost any clean-line, tie rod, integrated profile or trapezoidal slot cylinder.