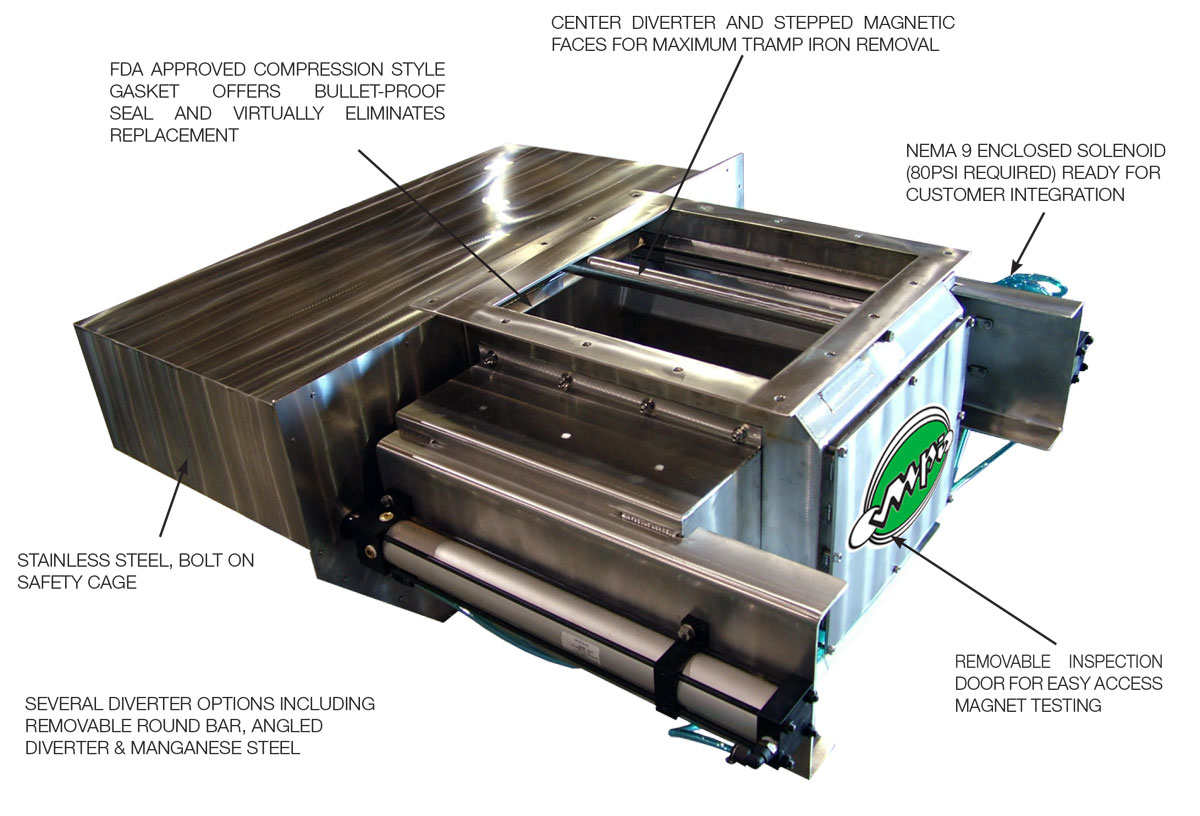

Description

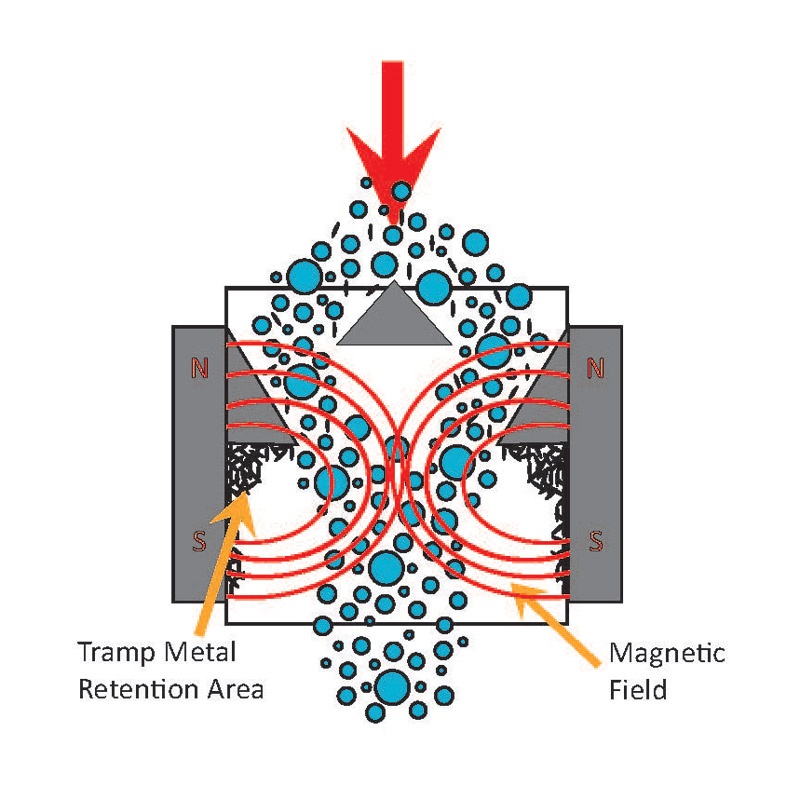

How the Self-Clean Chute Magnets Works:

The product stream flows between two large permanent magnets located on either side of the chute. A center diverter directs the product flow towards the two magnetic faces, which are stepped to minimize tramp metal “wash-off”. Tramp metal contaminants are “pulled” from the product stream and attach to either magnetic face. The pneumatically operated cleaning shell safely removes the tramp metal from the product stream to a disposal area outside the chute.

Self-Clean Chute Magnets Options:

- High energy Rare Earth magnet material

- 316L Stainless Steel construction

- Tramp metal collection trays

- NEMA 2 through 13 electrical enclosures

- Custom electrical components

- Chute transition adapters

- Custom diverter options

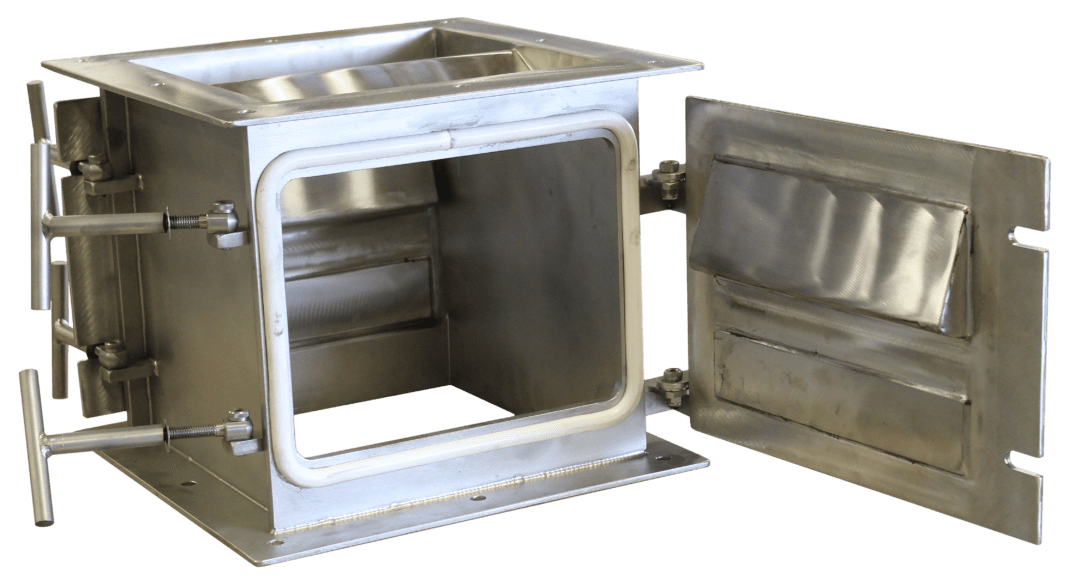

- Custom removable inspection door

- 3-cell design for large product flows