Description

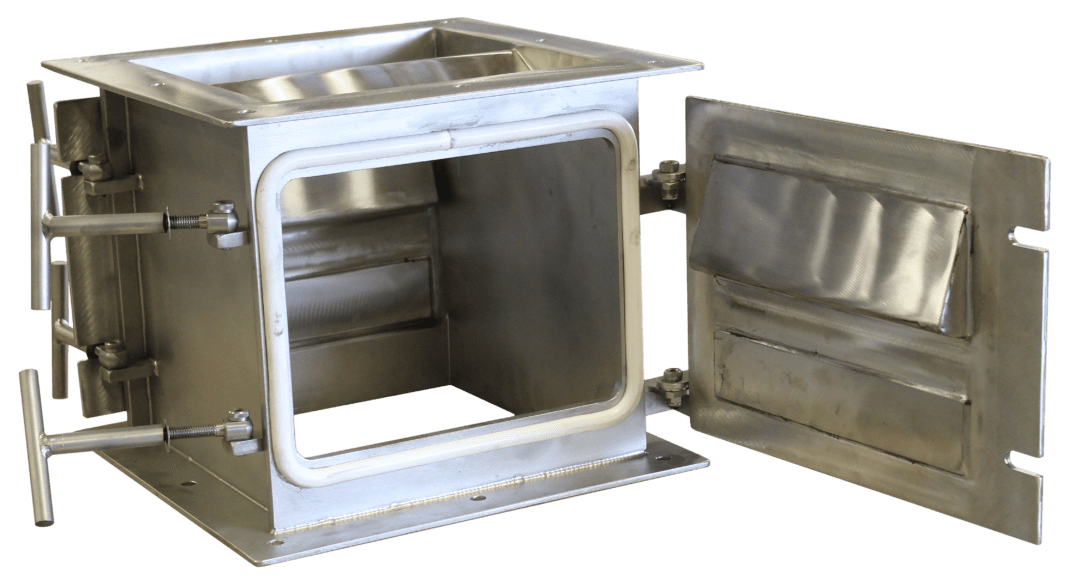

How the Manual-Clean Chute Magnet Works:

The product stream flows between two large permanent plate magnets located on either side of the chute. A center diverter directs the product flow towards the working surface of the two plate magnets, which are stepped to minimize tramp metal “wash-off”. Tramp metal contaminants are captured from the product stream and collected under the step of the plate magnet. The cleaning shell or operator safely removes the tramp metal from the product stream to a disposal area outside the chute.

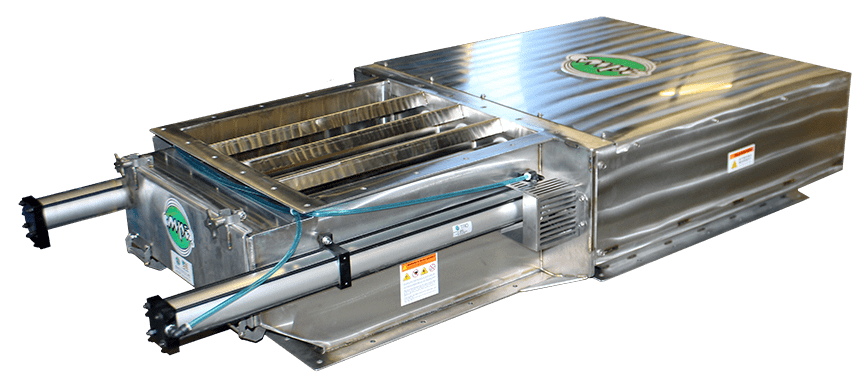

Manual-Clean Chute Magnet Options:

- Self-Cleaning designs

- High Energy Rare Earth magnet material

- Three-cell magnet designs

- Custom alloy stainless steel designs

- Tramp metal collection trays

- Chute transition adapters