Description

- No Phthalate. Titeflex only uses 100% PTFE, and conductive PTFE in the liner that remains flexible and does not leach.

- Design optimized for your specific application.

- Manufactured in long lengths to reduce hose costs associated with coupling hose sections.

- Economical and cost effective.

- Innovative PTFE technology by Titeflex satisfies the demanding aerospace, automotive, and industrial applications. The driving force is Titeflex commitment to safety, quality, value, and reliability. Modern quality production and customer satisfaction make Titeflex the leading PTFE hose producer.

Hose Construction

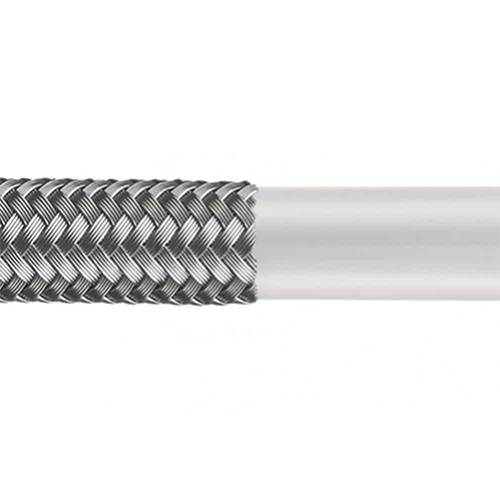

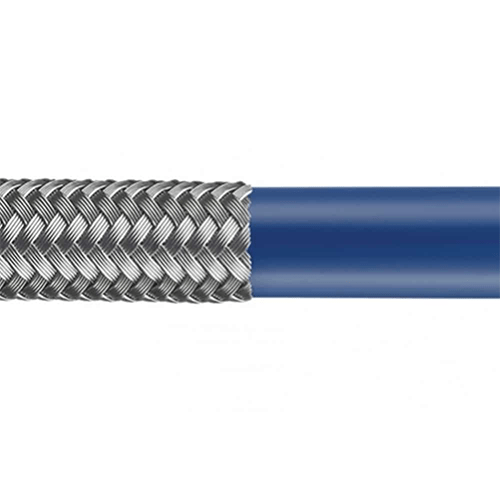

- Innercore vertically extruded to maintain highest quality of concentricity

- Manufactured from fine powder PTFE

- 304 stainless steel wire braid reinforcement

- The R115/R105 Non-Conductive Hose is made of 100% PTFE

Standards

- Meets or exceeds requirements of SAE 100R14

- PTFE meets FDA 21 CFR 177.1550

Vacuum Service

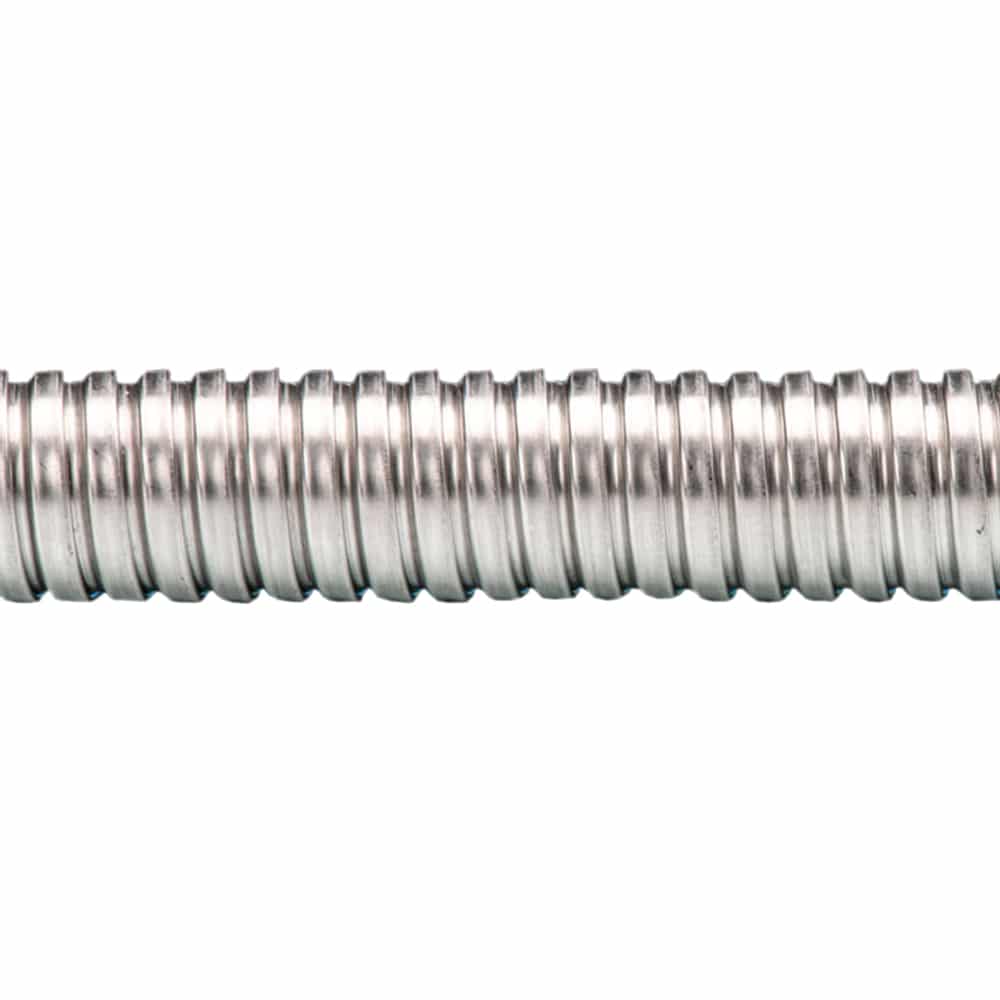

- Sizes -4 through -10 are rated for full vacuum

- Larger sizes -12 and above can be reinforced with an internal support spring for full vacuum service

Temperature

- -65°F to 400°F for Continuous Service

- -100°F to 500°F for Intermittent Service