Description

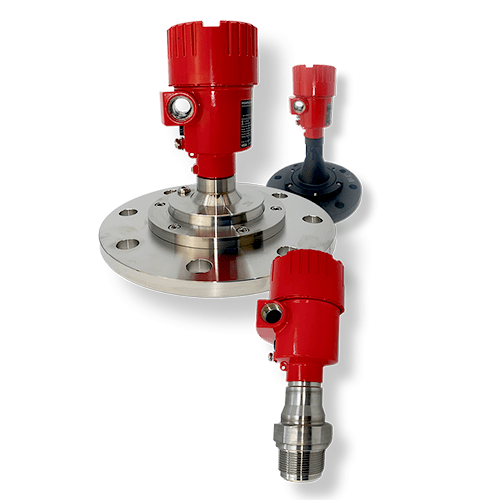

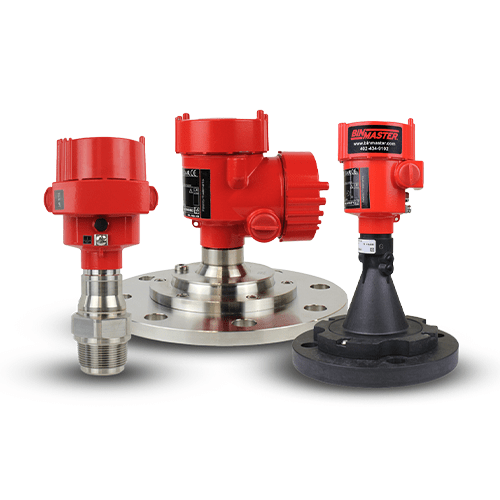

NCR-86: The Radar for Solids AND Liquids

The BinMaster NCR-86 is a universal radar sensor for continuous level measurement of liquids and bulk solids for all process conditions.

Configure the sensor using the BinMaster Sensor App on your phone or PC or use the BinDisc module to quickly set up the NCR-86 for any application.

Configurations to customize your-86 radar

- Aluminum, plastic and stainless-steel housing

- 2- or 4-wire 4-20 mA/ HART and Modbus outputs

- Adapter flanges, mounting straps or swiveling holders

- Non-EX or with CSA, ATEX, or IEC approvals

Robust construction, rugged enclosures, and encapsulated electronics ensure the NCR-86 works reliably and safely even in excessive conditions.

NCR-86 makes monitoring inventory easy

- Inventory access from BinCloud

- Fast and accurate in challenging conditions

- Non-contact, maintenance-free operation

- One sensor configures to any application

What’s great about the NCR-86

- Solids or liquids: It’s adaptable to material of any bulk density or specific gravity.

- Accuracy and measuring range: Accuracy of ± 1 mm at distances up to 393′ or 120m.

- Protection from cyber-attacks: Designed to IT Security standard IEC 62443-4-2.

- Hot temperatures, high pressure: Process temps to 842°F, process pressure to 160 bar.

- Immune to extreme environments: Accurate in excessive dust, steam, or noise.

- Functional safety: SIL, IEC 615111 to reduce failures and protect from hazardous events.