The METAL SHARK® 2A controller sets a new industry benchmark for performance, user-friendliness, and ease of data storage. Improved performance results from Cassel′s exclusive Four-Quadrant technology, which allows for a 360-degree freestyle teach area around the product effect, significantly increasing sensitivity. Cassel equipment readily adjusts settings to detect metals even in such products as cheese and high-salt content foods, where detection can be a challenge.

Digital Balance Control adjusts for temperature and humidity fluctuations by monitoring coil balance more than 200 times per second.

Digital Frequency Control utilizes synthesizer technology to generate a constant and stable frequency and phase during extended use.

Digital Dynamic Noise Filter reduces or eliminates electronic and vibration signals in the environment, creating a more reliable signal.

Quick teach with graphic assist allows the Metal Detector to be operational in less than 10 passes.

Intuitive operation: A full-color 5.4″ display panel shows only the information needed to operate the detector. Easy-to-follow software and a simple teaching menu allow set up and use by non-technical personnel. Over 120 products can be stored and recalled. A four-level password protection system ensures that only authorized users can operate the equipment. Operators can easily call up histograms, reports, diagrams or help screens. Performance Validation Software (PVS test) automatically notifies the operator when testing is required.

No maintenance electronics: Automatic balance and calibration of electronics ensure many years of reliable performance. After the initial set up, no further adjustment of electronics is needed. Single frequency is standard. Multi-frequency is an available option.

Sensitivity + Stability = Satisfaction: New “recipes” or changes to current data are easily programmed. Digital noise filters eliminate any undesired signals, while multi-channel technology provides optimum detection of ferrous, nonferrous or stainless steel contaminants. The integrated sensor is built to withstand the rigors of harsh production settings. Key internal electronics are fully protected and reliably perform in even the most challenging wet or dry environments.

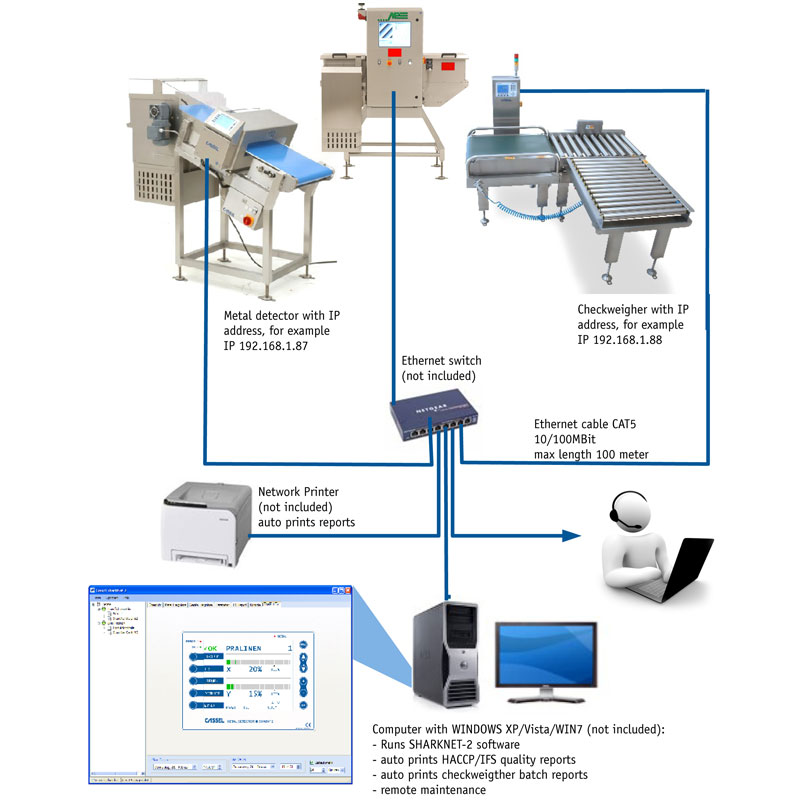

HACCP and IFS compliance: HACCP and IFS compliance: Per HACCP principles, Metal Detectors are considered a critical control point and require continuous checking to meet standards. Metal contaminant detections, changes in parameter settings, etc., are logged with both the date and time. Users can easily view reports and download information to a Windows-based PC. Ethernet option is included.

Compatible Windows software: SHARKNET® 2A

Stainless steel enclosure: Module is housed inside a stainless steel enclosure, fabricated up to IP69K. Other optional enclosures are available for wet or wash-down environments.

Remote support via Internet: With the METAL SHARK® 2A Controller and an optional Ethernet module it is possible that a Cassel Service engineer can perform remote support on the metal detector. This can save high traveling costs for service engineers.