Description

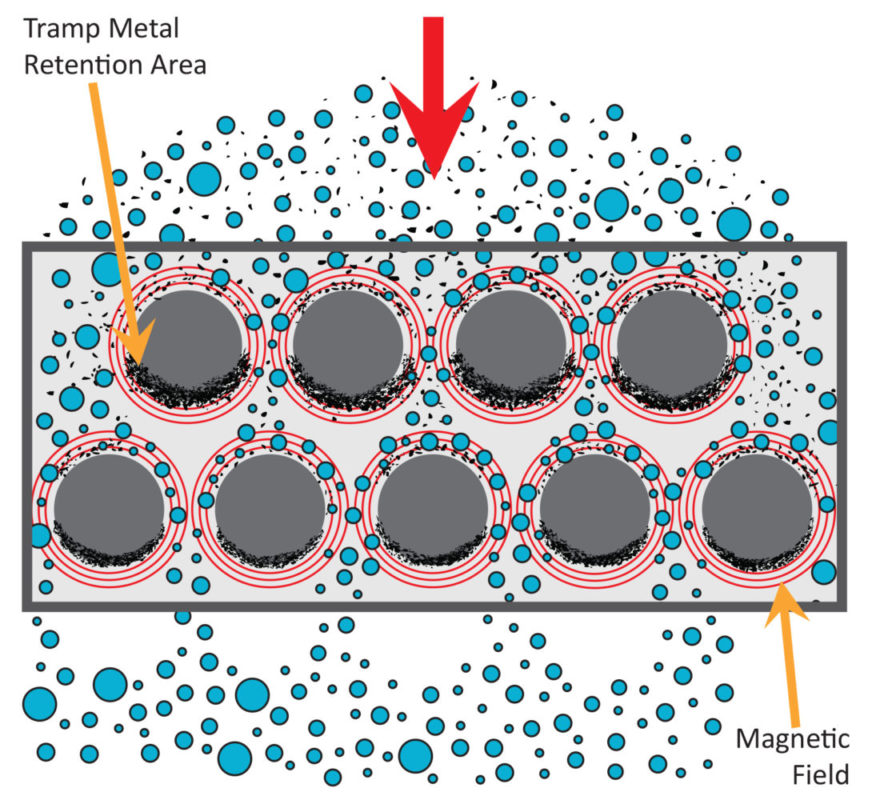

How the Manual Clean Drawer Magnet Works:

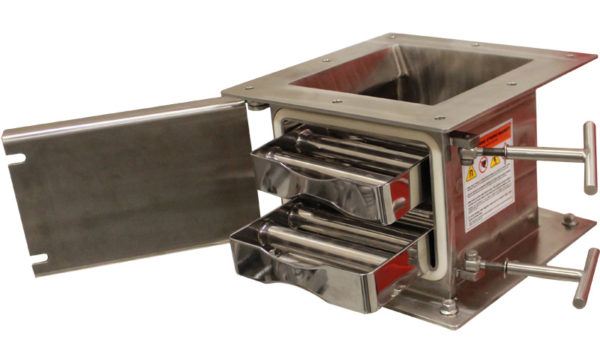

The product stream flows through two tiers of 1” diameter magnetic tubes designed to create an extremely effective magnetic circuit. The two rows of magnetic tubes are staggered to prevent bridging or choking of the product stream and maximize magnetic filtration as product flows through the housing. Tramp metal contaminants move to the underside of the magnetic tubes, eliminating tramp metal “wash-off.” After terminating the product flow, the hinged door can be quickly unlatched and opened to allow quick removal and cleaning of each magnetic drawer.

Manual Clean Drawer Magnet Options:

- Cleaning Method:

- Manual clean

- Manual quick-clean

- Automated self-cleaning

- Continuous automated self-cleaning (standard)

- Number of Tiers of Tubes:

- 200 Series with 2 tiers of tubes

- 400 Series with 4 tiers of tubes (standard)

- 600 Series with 6 tiers of tubes

- Material Construction:

- 304 Stainless Steel (standard)

- 316 Stainless Steel

- Magnetic Tubes:

- Ceramic

- REN Rare Earth (standard)

- Hi-G high-performance Rare Earth

- TW Thin Wall high-performance Rare Earth

- Magnetic Material Temperature:

- 400°F @ 3.5 MGO (ceramic)

- 176°F @ 52+ MGOe (rare earth) (standard)

- 248°F @ 48 MGO (rare earth)

- 356°F @ 38 MGO (rare earth)

- 662°F @ 30 MGO (rare earth)

- Tube Spacing:

- 2” horizontal and 3.250” vertical spacing (standard)

- 3” (approx.) horizontal and 3.250” vertical for increased flowability

(recommended for products that bridge or choke) - Custom configurations available

- Tube Coatings:

- Stainless steel with no coating (standard)

- Synergistic Coating

- Gasket Material:

- White silicon, FDA approved (standard)

- Buna, FDA approved

- Metal detectable blue silicon, FDA approved

- Position Switch: For unit closed confirmation or safety interlock

- Not included (standard)

- Proximity switch for unit closed confirmation (MPI Standard model and mount)

- Mechanical safety switch for unit closed confirmation and safety (MPI Standard model and mount)

- Switch mounting bracket only (customer supplied switch)

- Customer specified model

- Transitions: Stainless steel transitions for easy installation

- Not included (standard)

- Inlet, outlet or both, configured as required for installation

- Companion Flanges: Matching companion flanges for the customer to weld onto existing chute work for easy installation

- Not included (standard)

- Stainless steel companion flanges

- Carbon steel companion flanges

- Housing Vibrator: Housing mounted vibrators improve product flowability over magnetic tubes

- Not included (standard)

- Pneumatic vibrator