Description

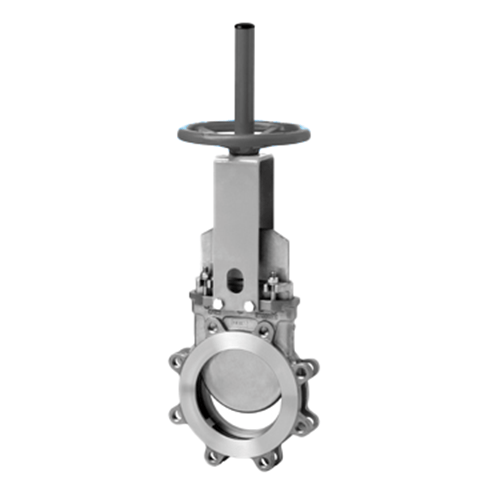

Knife Gate Valves Features:

BENEFITS

- Reliability of operation

- The cast body of the valve is dust-tight assuring a clean operation

- Knife action to cut through a standing column of material

- Short opening and closing time

- Maintenance is easy with replaceable packing

- Modular design permitting upgrades to packing and operators

INDUSTRIES WHERE USED

Bulk Powders, Cement, Chemical, Fly Ash, Iron Ore, Lime, Mining and Minerals, Steel Mills

FEATURES

- Cast iron body

- Round flange

- Stainless steel gate

- Dust-tight design

- Stuffing box with replaceable packing

- Self-cleaning design

- Non-jamming operation