Description

-

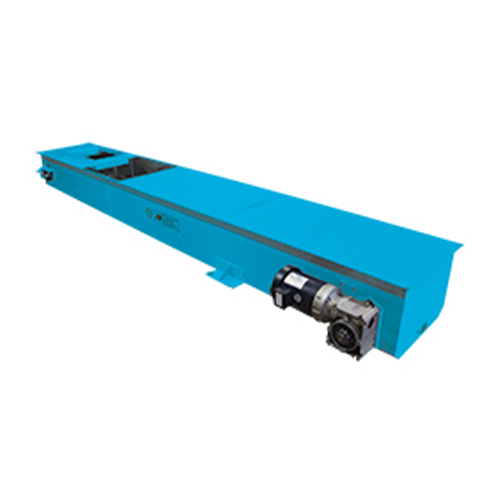

Style A

• Usually straight horizontal feeder conveyors under a large press bringing the scrap out to an inclined conveyor to the dumpster

• Manganese slider-bed option for additional wear resistance

• Up and over stairs and mezzanines available

Style B

• Horizontal to incline design brings scrap out from under press into a tote.

• Standard fixed supports or optimal mobile bases available.

• Strong ceramic or rare earth magnets on centers from 12″ to 36″ depending on scrap size.

• Manganese slider-bed option for additional wear resistance.

Style C

• A nose-over unit designed for extending over scrap dumpsters.

• Optional side guards or flared in-feed hoppers available to direct scrap & chips onto the magnetic elements.

• Taller side guards with drain tubers or perforated side guards for coolant.

• Manganese slider-bed option available for additional wear resistance