Description

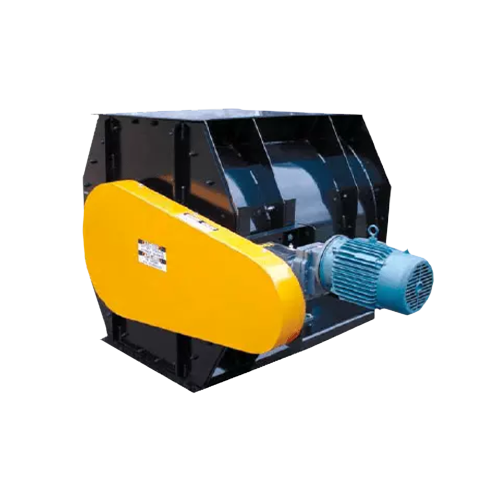

COMMON SERVICE CONDITIONS

- Pressure Rating: 22 PSI

- Maximum Operating Temperature: 250°F

- Materials: Dry Free-Flowing Extremely Abrasive Particles

TYPICAL APPLICATIONS

RELEVANT INDUSTRIES

Power – Fly Ash, Coal

Cement – Kiln Dust, Raw and Finished

Asphalt – Limestone, Granite

Steel – Oxides, Grinding Dust, Sinter

UNMATCHED COMPETITIVE ADVANTAGES

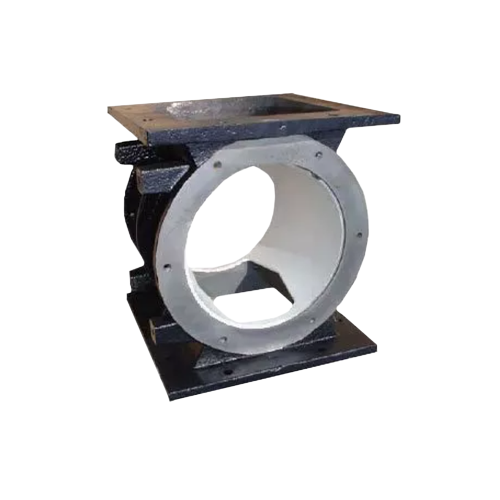

CERAMIC

- Precision-Cut ceramic tiles bonded in place minimizing gap exposure

- Closed-End rotor designs with ceramic tiled end disc perimeter and tungsten carbide tips for prolonged wear resistance

- HVOF spray-on packing area for extended shaft life

- Ceramic can be re-ground for additional life

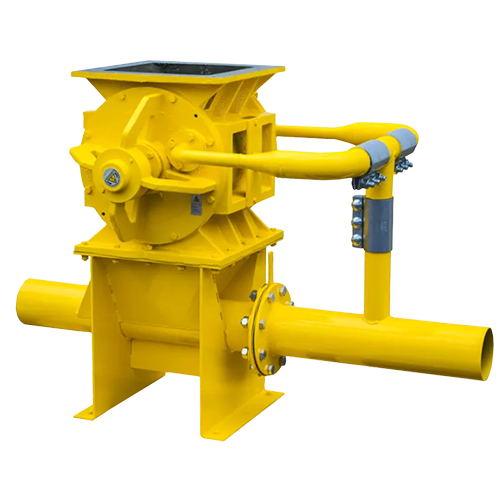

DURAKAST

- Oversized housing thickness designed to be re-ground for many years of service

- Pre-Cast flange holes allow for easy field installation on new or replacement units

- Closed-End rotor with welded hard-faced stellate tips for maximum wear resistance

- End plates are hard chrome lined with an optional purging feature

- Higher pressure differentials for highly abrasive applications 650 Bhn high chrome wear resistant casting for maximum life