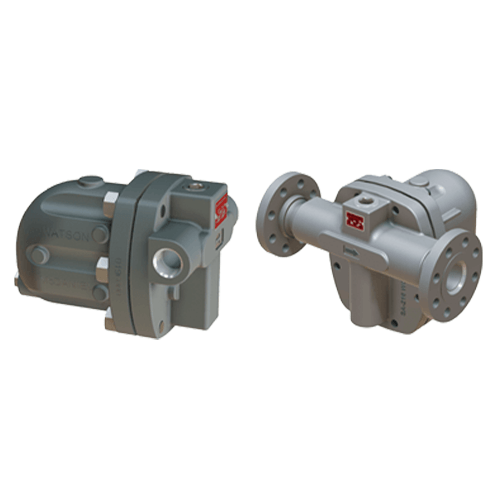

Description

FTE / FTES Float & Thermostatic Steam Traps have Ductile Iron Bodies and FTES-Series have Cast Steel Bodies. These Float and Thermostatic Steam Traps are intended for use on steam process applications with very high condensate load requirements. Examples include re-boilers, absorption chillers, large air-handling equipment and heat exchangers. They contain a high quality welded stainless steel thermostatic air vent and all stainless internals. F&T traps have excellent air-handling capability, making them the preferred choice for most process applications.

Float and thermostatic traps contain a float and seat mechanism with a separate thermostatic element which work together to remove both condensate and air from the steam system. The float, which is attached to a valve, rises and opens the valve when condensate enters the trap. This allows the condensate to discharge. Air is discharged through the thermostatic air vent to the outlet side of the trap. Steam entering the trap causes the thermostatic element to expand, closing the air vent and trapping the steam.

Application Data Sheet – Fill Out and Return for Accurate Quote