Description

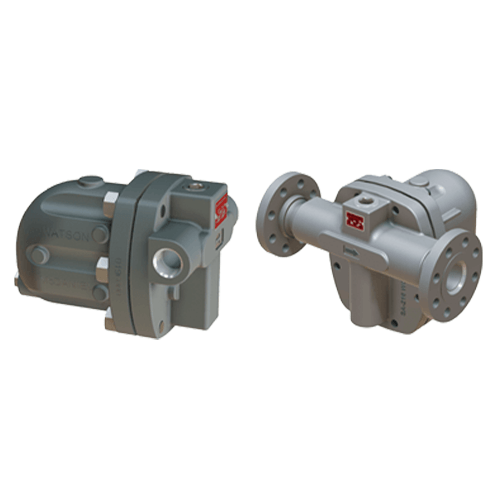

FT600 (Cast Steel) 3/4″ – 2″ Steam Traps feature:

- Cast Steel Bodies

- Stainless Steel Internals

- 450 psig Operating Pressures

- For use with applications with Higher Pressures or where Steel Bodies are specified

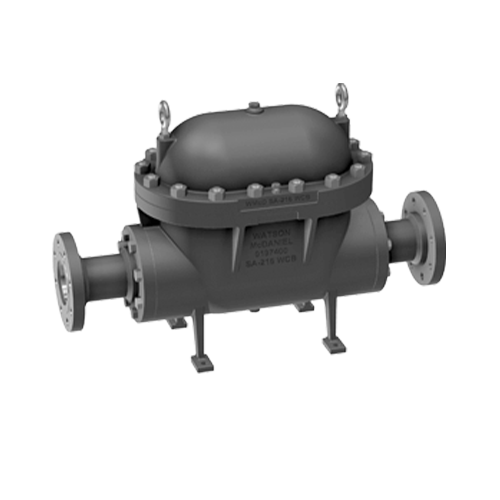

Traps with Steel Bodies are often required in chemical plants and petrochemical refineries and used on re-boilers, heat exchangers, and other process applications.

Float and thermostatic traps contain a float and seat mechanism with a separate thermostatic element which work together to remove both condensate and air from the steam system. The float, which is attached to a valve, rises and opens the valve when condensate enters the trap. This allows the condensate to discharge. Air is discharged through the thermostatic air vent to the outlet side of the trap. Steam entering the trap causes the thermostatic element to expand, closing the air vent and trapping the steam.