Description

Application Data Sheet – Fill Out and Return for Accurate Quote

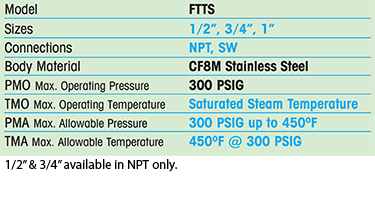

FTT Float & Thermostatic Ductile Stainless Steel Steam Traps feature:

- Stainless Steel Bodies

- All Stainless Steel Internals

- 225 psig Operating Pressures

These Steam traps are used where frequent System wash down is required or when rust and other surface corrosion cannot be tolerated such as in facilities used for Food and Beverage or Pharmaceutical production.

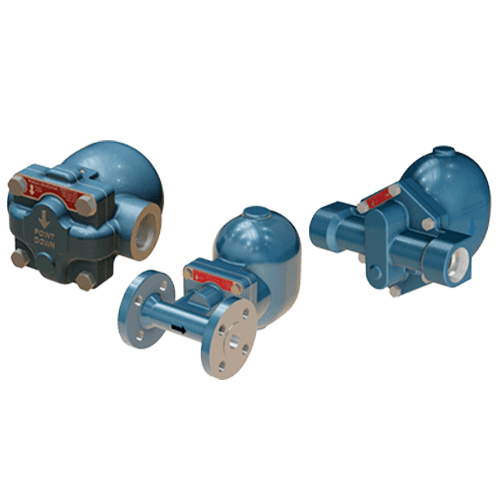

Float and thermostatic traps contain a float and seat mechanism with a separate thermostatic element which work together to remove both condensate and air from the steam system. The float, which is attached to a valve, rises and opens the valve when condensate enters the trap. This allows the condensate to discharge. Air is discharged through the thermostatic air vent to the outlet side of the trap. Steam entering the trap causes the thermostatic element to expand, closing the air vent and trapping the steam.