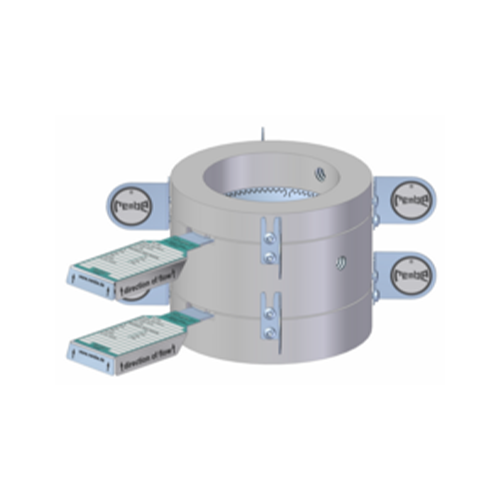

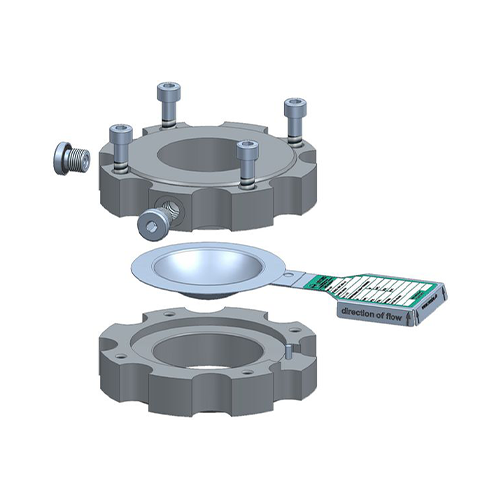

Double Disc Assembly

Double disc assembly provides double protection for production equipment working under extreme conditions, e.g. with highly corrosive, environmentally harmful or highly toxic substances. Both rupture discs in this unit burst in case of excessive pressure and thus protect the system. The area between these two discs is continuously monitored by a pressure measuring unit. If for instance corrosion, damage or any other factor leads to premature failure of the rupture disc on the system side, any leakage is detected by the pressure monitoring device between the two discs without the second downstream connected rupture disc reacting.

Another application for double rupture discs is the definitive initiation of a triggering/bursting operation. As an example, it is possible with two discs of differing bursting pressure to introduce pressure into the area between the discs. If the pressure is to be relieved, the evacuation of the intermediate area triggers a burst under system pressure.

The response pressures of the two discs depend on the operating conditions. Double disc assemblies are installed as insert units between welding neck flanges to DIN or ANSI standards. The flow direction must be observed during installation. All double disc assembly mounting units have pre-assembly bolts facilitating assembly to the rupture disc prior to installation in the pipeline or flange connection.