Description

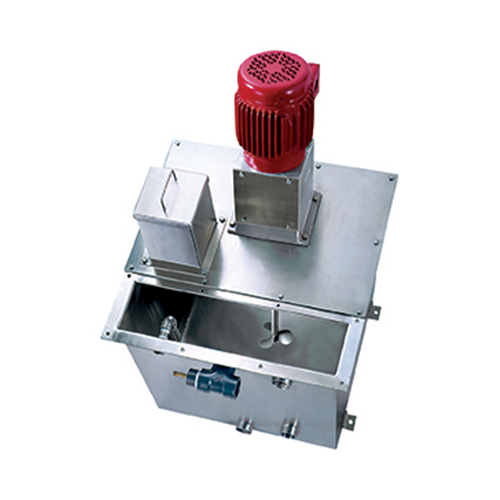

Dissolving Tanks Specifications:

- Solenoid valves, level probes, float valves, rotometers and other related equipment

- Hydraulic mixing jets constructed of PVC pipe with 304 stainless steel jets

- Surface jets to enhance wetting and dust control

- Accessories to produce constant strength solutions or slurries

Wetting Cones Specifications:

- Booster pump for applications with low available water pressure

- Solenoid valves, level probes, pressure switches and other related equipment for automatic operation