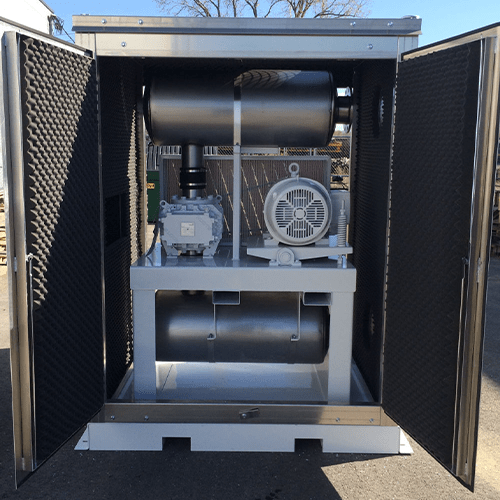

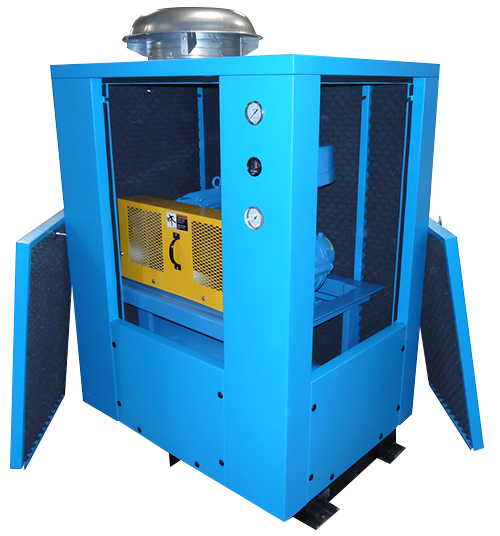

Custom Sound Enclosures

JL Components industrial sound enclosures or “noise enclosures” are custom made per your requirements. We can accomodate multiple metal types, spec fan motors, foam density/thickness…your options are endless!

A common practice in plants is to use “sound blankets” to address noisy equipment. Custom industrial noise enclosures by JL Components are superior to sound blankets for many reasons: initial cost, life expectancy, ventilation, cleanliness, attenuation performance, maximum equipment access, and reduced labor during installation.

Quick and Easy Installation

One benefit of aluminum noise enclosures is the lightweight construction. Installation is as easy as lifting the unit over the top of the equipment and lowering it down with a forklift. We recommend you bolt the enclosure to the floor or sub-base, connect your inlet or discharge piping, mount and wire the ventilation fan, and you are done!

Cost Effective OSHA Solution

During the planning phase of a new project, you may evaluate whether a dedicated blower room or even a completely new structure is required. Not only is this a costly proposition but now hearing protection is required to enter the structure. Typical industrial sound enclosures from JL Components reduce sound attenuation by 20dB which allows you to facilitate your equipment and utilities in the same building/room.