Coolant and Machining Sensors

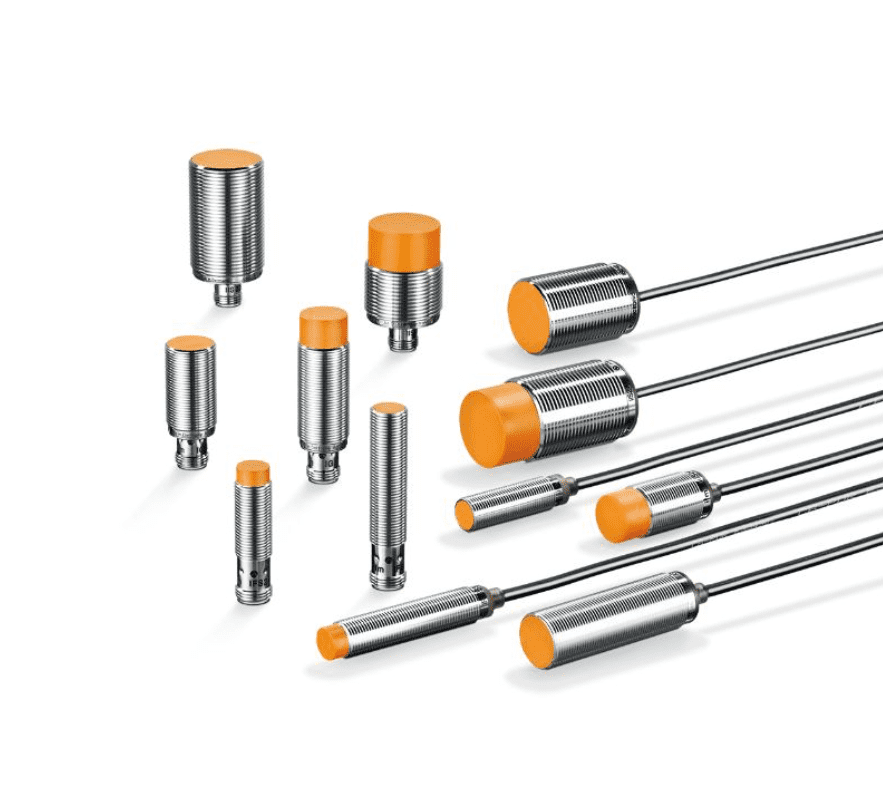

These unit series were specially developed for metalworking applications.

Oils and coolants heavily impact the machine components installed in machine tools. Standard sensors are insufficient in many applications. The C series has been specially designed for this industry segment. The sealing concept of the sensors combined with the suitable ecolink connector ensures maximum protection against malfunctions.

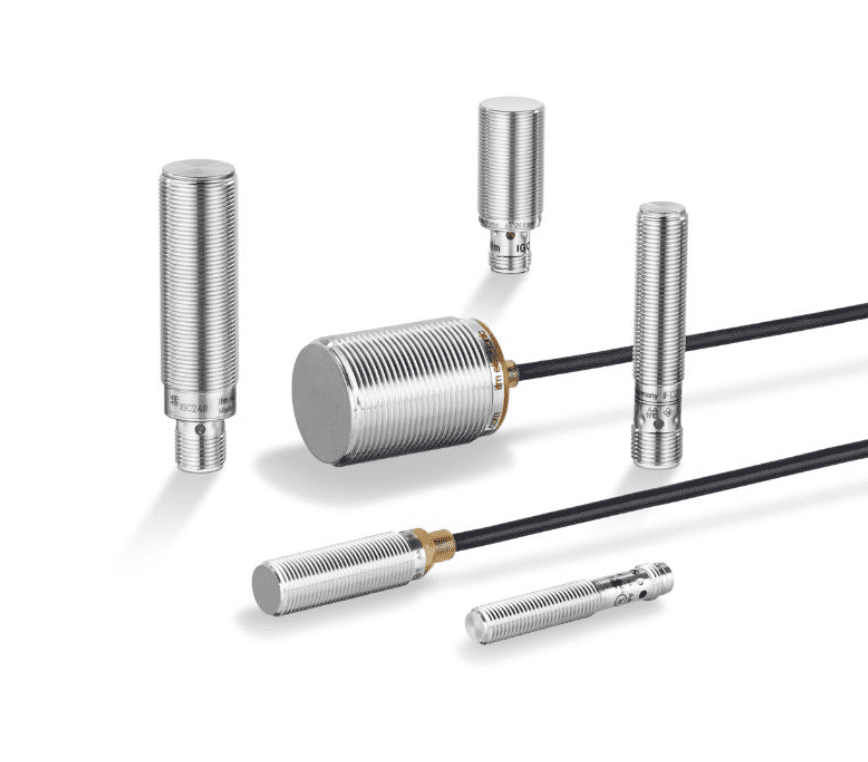

The threaded body and the sensing face of the one-piece housing of the full-metal sensors are made of high-grade stainless steel. The robust material is corrosion-resistant and allows installation of the sensors in extreme applications.

Sensors with increased sensing range, correction factor K = 1 (same sensing range on all metals) or K = 0 ( only detects ferrous metals) are ideal for metalworking applications. Sensors with K = 0 are insensitive to aluminium chips. This is a special advantage when engine parts made from aluminium are machined and the chips must not influence the sensors.

- For metalworking applications

- Sensors and connectors in perfect combination for use in oils

- Metal sensing face for heavy duty

- High shock and vibration resistance

- Permanently legible laser type label