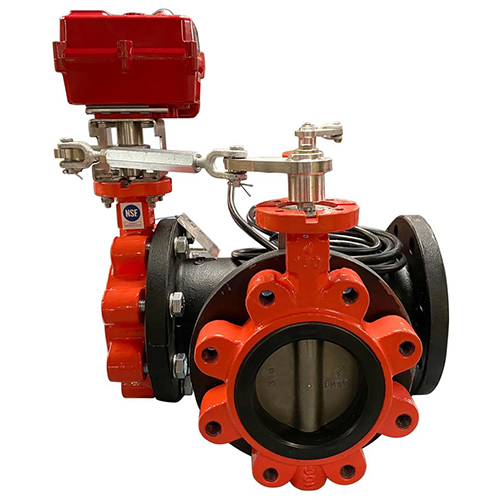

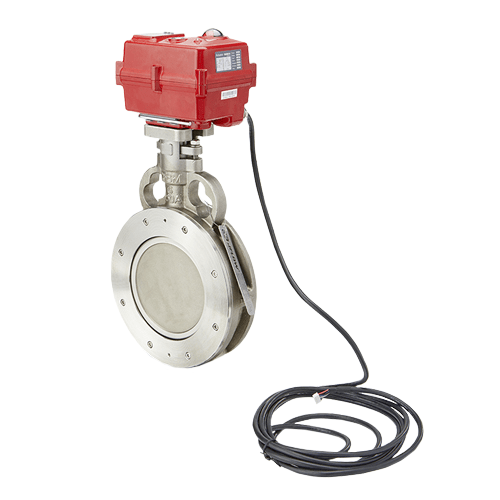

80 & 81 Series Resilient Seated Butterfly Valve

- API Standard 622

- Soft seated cartridge seat type butterfly valve

- One piece body construction, direct mount

- ISO 5211 mounting pad

- NSF61 certified

- TAA compliant

Features & Benefits

- One piece body construction of ductile iron, cast iron or Stainless Steel and complies with API 609, MSS SP 67, and ISO 5752

- ISO 5211 mounting pad with square or key type stem shaft permits direct mount actuation for both manual (lever and gear), pneumatic and electric operations

- Teflon stem bushing to assure long life even during extended period of activity. Lower operator torque for easy manual operation and maximum shaft support

- High strength two-piece stem eliminates taper pins or disc screws, which often fail prematurely through abrasion, corrosion or fatigue

- All disc castings are spherically machined and polished for extended seat life and bubble tight shut off

- Seat type available in both encapsulated phenolic or aluminum-backed cartridge seat. Cartridge design seat permits easy change without special tools

- Reduced disc option for lower pressure applications, requiring lower torque and smaller actuators

- Conforms to API 598 and MSS SP 61. Shell tested to 150% and seat tested to 110% of maximum working pressure

- Full rated disc, lug body valves are rated for 150 psi in dead end service

- Live loaded packing

Application Data Sheet – Fill Out and Return for Accurate Quote