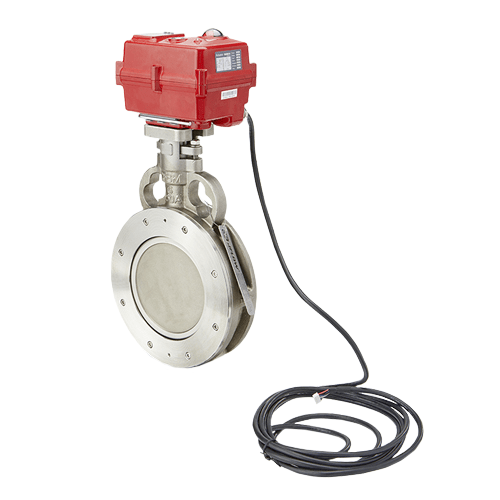

Description

SIZE

- 2″ – 24″

BODY MATERIAL

- A216 WCB Cast Steel

- A351 CF8M Stainless Steel

DISC

- Stainless Steel CF8M

PRESSURE RATING

- Class 150# & 300#, 600#

- PN10, PN16, PN25, PN40, PN63, PN100

- DIN

- JIS

OPERATION

- Lever

- Gear

- Pneumatic

- Electric

SEAT MATERIALS

- Soft seat: TFM-4125, PTFE, RTFE, NBR, EPDM, FKM

- Metal seat: A240 Tp 316/304

TEMPERATURE RATING

- -62°F to +600°F

VALVE RATING

- Top flange mounting pad: ISO 5211

- Basic design: API 609, MSS-SP-68, BS 5155, ISO 5752

- Pressure/Temp Rating: ANSI B16.34

- Shell/Seat Test: API 598, MSS-SP-61

- Working Pressure: Class 150 (285 psig); Class 300 (740 psig)

- Metal to metal seat leakage is rated at Class IV per ASME/FCI 70-2

I & M

82 & 83 Series I & M

OVERVIEW

J Flow Control Valve & Butterfly Product Overview

J Flow Automation Capabilities Overview