This Loss-In-Weight Feeder Never Needs Calibration

Acrison is a feeder and bulk material handling equipment manufacturer making dry bulk material processing equipment in Moonachie, New Jersey US

A since the early 1960’s. In that time, they created and originally patented the only loss-in-weight feeder that never needs calibration.

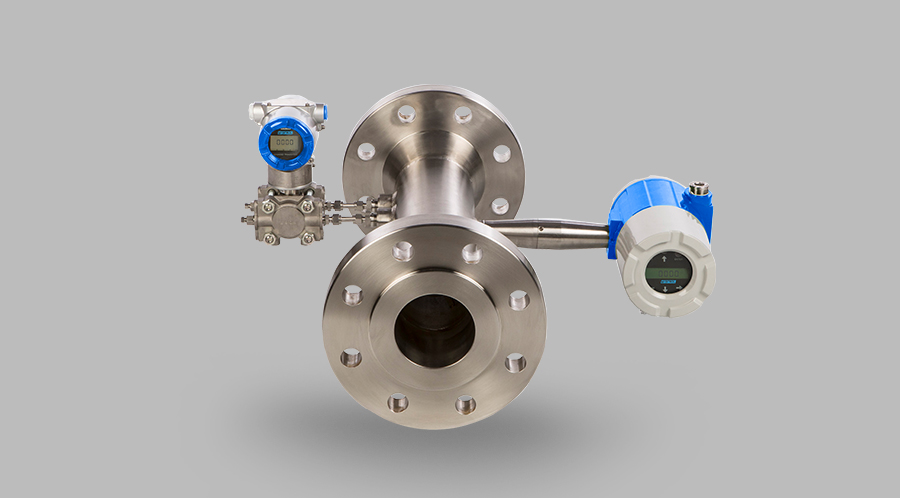

Feeders are used in all sorts of manufacturing industries to properly disperse dry material at a very accurate rate. When pinpoint accuracy is needed, the feeder gets mounted to a scale so that you can monitor the real-time weight discharge from the feeder screw. This allows you to modulate the speed up and down to make rate.

Acrison’s competitors all use load cells which are small strain gauges that measure .003″ of travel and convert that change in resistance through an amplifier to an output signal. Basically, it takes a very fine amount of movement and tries to quantify how much weight is in the hopper.

Two things are non-desirable about this:

- Load cells fall out of calibration easily. Almost all load cell feeders or equipment need to be calibrated annually at the minimum. This means you’re going to be paying a tech or rep to come in and manually recalibrate this process. It could also mean downtime.

- They take such a small amount of movement and amplify that signal to make a recognizable output signal. What this means is if you’re off a little on the load cell, you’re going to be off a lot on the final output signal. This is sort of like being off 3 degrees when you are driving the golf ball off the tee. 3 degrees doesn’t sound like much, but it could be the difference between hitting the fairway and landing in the rough.

Acrison uses their patented Ratiometric Digital Weight Resolver which attaches to a flexure-based scale.

What are the benefits of this system?

- The flexures that handle Acrison’s scale are made of 316SS and have a known flex distance.

- The RDWR travels .18″ or almost 60x more than a load cell has. This means it doesn’t need to be amplified.

- The RDWR has over 1,000,000 parts of resolution so your accuracy is far superior to anything load cells can accomplish.

- They are made 100% in the USA. This allows for fast shipping on parts, solid lead times, and any service you might need is always a phone call away!

- The return on investment or total cost of ownership is much less when compared to a typical competitor’s feeder.

- The best part: It never needs to be calibrated again once it leaves the factory.

Apex has enjoyed promoting the Acrison line for the past 6 years. You can count on Apex to have a solution for all your feeding applications!