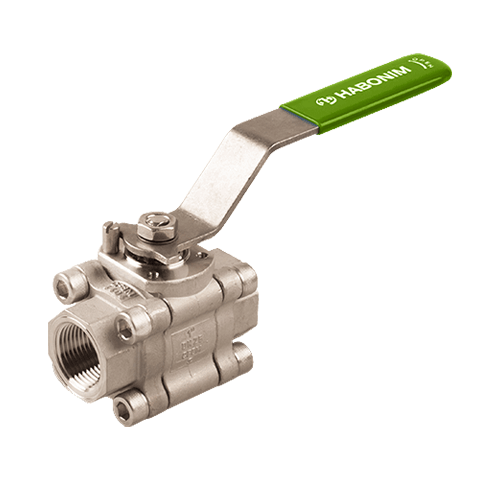

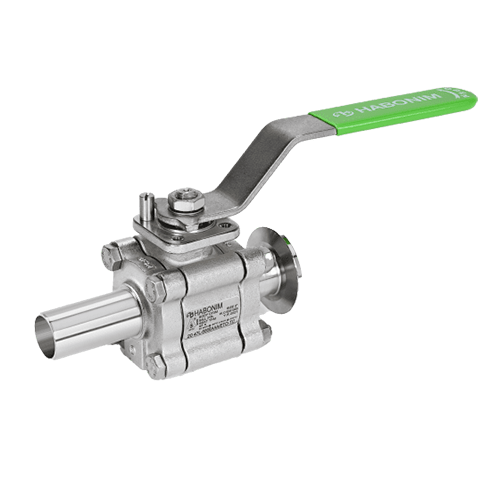

Description

Size Range: 3/8″ to 4″ (DN10 – DN100)

Pressure Range: Class 900/400

- Tube size for ISO or DIN sized tubing

- Forged or cast

- ANSI B16.34 Class 900 (wall thickness), size ¼”-2” (DN8-DN50)

- ANSI B16.34 Class 400 (wall thickness), size 2 ½”-6” (DN65-DN150)