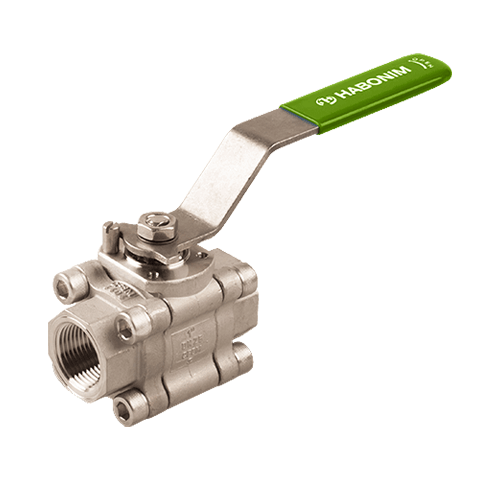

Description

Size Range: 1/2″ to 6″ (DN15 – DN150)

Pressure Range: Class 300

Comply with the ASME BPE standard for applications in which cleanability and drainability are essential for product quality.

Patented HermetiX™ stem seal, made from FDA-approved polymer materials. The valve port diameter is identical to the tube inner diameter so that no expansion or contraction can take place inside the system, resulting in full drainage and zero traces that could cause contamination.

“To provide superior welding quality, to avoid rouging on austenitic stainless steel surfaces, and corrosion attack on welding areas, Metal parts are defined, as standard, with low ferrite and controlled sulfur”. Upon request a forged 316L stainless steel material with ferrite content less than 1% is also available.