Description

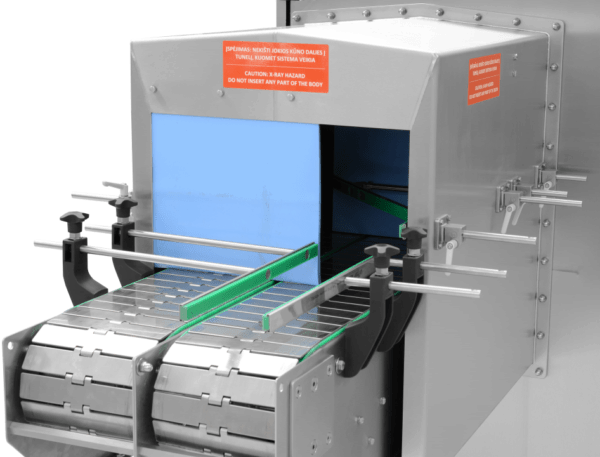

How the X-Ray for Glass, Jar, and Can Lines Works:

X-Ray inspection is sorting based on product density. An X-Ray inspection machine takes an image that is pixel based. The machine compares pixel density to stored pictures of “good” product to detect defects and contaminants. If the density of a product falls outside of acceptable range the reject mechanism removes the contaminated product out of the product flow.

Options:

- Optional reject systems include, but not limited to:

- Push Arm

- Air Blast

- Multiple Lane

- Flap at Belt End

- Additional options:

- Lockable Reject Bin

- Curtainless systems including extended infeed/outfeed tunnels