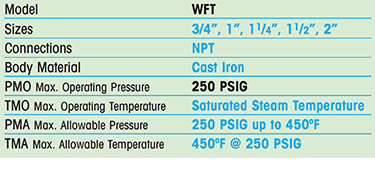

Description

Features:

- Cast Iron Bodies

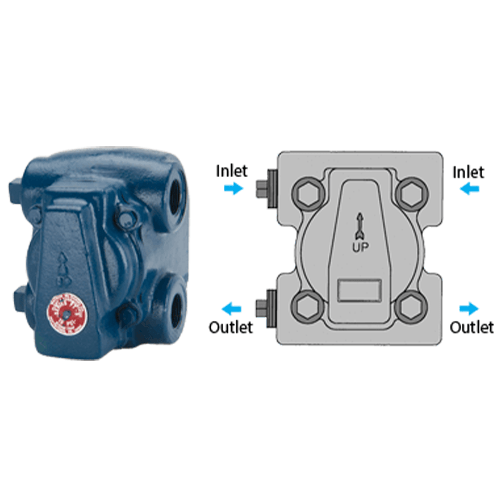

- Parallel Port Connections

- 250 psig Operating Pressures

- Stainless Steel Internals

Typically used on steam process applications such as unit heaters, pressing machines, heat exchangers, steam coils. They contain a welded stainless steel thermostatic air vent for rapid air removal on system start-up and all stainless steel internals.

The PMO rating of model selected must meet or exceed the maximum steam pressure. If it is less than the max steam pressure the trap may not open.

For Example:

The WFT-125 has a PMO of 125 psi. Condensate capacity (lbs/hr) of the trap is based on the differential pressure across the trap. For drip applications, a 3/4″ WFT size is generally sufficient to exceed warm-up loads with a 2X safety factor.

The condensate loads (lbs/hr) for process applications are normally calculated at the maximum steam pressure. Then an appropriate safety margin is applied in order to select a trap with sufficient capacity when operating at lower steam pressures.

When a temperature control valve regulates the flow of steam to the process equipment (Heat Exchanger) being drained of condensate, it is recommended to select a trap with a PMO that exceeds the inlet steam pressure to the temperature control valve. This assures that under all operating conditions, the steam pressure will not exceed the PMO of the trap.

For Example:

Process application has a maximum steam inlet pressure of 100 psi, a maximum condensate load of 2,500 lbs/hr and is discharging to a condensate return line with a possible back pressure of 25 PSIG. ΔP = 100-25 = 75 PSI

To select trap:

If the Safety Load Factor is chosen to be 2X max capacity at max differential pressure, then Trap should be selected based on 5,000 lbs/hr (2,500 x 2 = 5,000) at 75 PSI differential pressure with a PMO in excess of 100 PSIG

Selection:

WFT-125-17-N, PMO=125 PSIG, 2” NPT with a condensate capacity of 7,460 lbs/hr at 75 PSI differential pressure.

Application Data Sheet – Fill Out and Return for Accurate Quote