Description

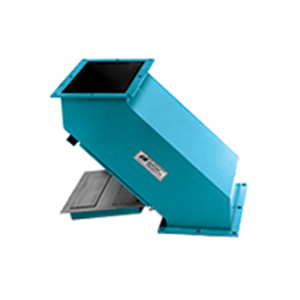

Grate magnets can be installed or simply laid inside the following:

- Hoppers

- Pits

- Chutes

- Housings

- Bins

There they can be easily accessed for cleaning. Grate magnets are offered in food, sanitary and USDA finishes. Grate magnets come standard with neodymium rare earth magnets, although ceramic and NUHI™ Neo Ultra High Intensity magnets are also available. Grates are economic solutions for your critical control points to help catch any ferrous metal.

It is extremely important to determine the correct cartridge with the right magnetic strength for your unique application—stronger is not always better. While every application is different, Bunting offers such an extensive selection of magnetic cartridges and grate magnets that we are certain we will be able to provide you with the optimal magnetic separation solution for your production environment. Our engineers are magnet experts who can assist you at every single step of the design process. We design custom solutions for your industry. For example, for customers in a food environment, most of our cartridges and grates meet the food standard 10,000 gauss and food weld clean up.