Description

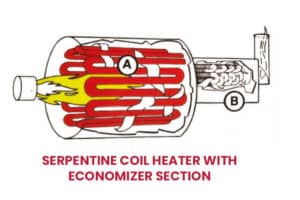

Benefits of Serpentine Coil Heater Design

Hot oil heaters that feature serpentine coils offer a number of advantages over conventional hot oil heaters, including:

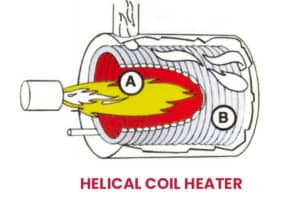

Higher Efficiency: Serpentine coil heaters are 10 to 15% more efficient than hot oil heaters that feature helical coils. As an example, when switching from a helical to a serpentine coil thermal fluid heater with a maximum load of 2MM Btu/hr, the fuel cost savings per year can be upwards of $270,000. The fuel savings in one to two years will pay for the equipment itself!

Low Level of Fluid Degradation: Heating fluid lasts longer when utilized with a serpentine coil heater.

Higher Operating Temperatures: Typical hot oil heaters offer limited operation at fluid temperatures over 400°F, but serpentine coil hot oil heaters can operate efficiently at temperatures up to 650°F.

Long Tube Life: Tube failures are common in hot oil heaters featuring helical coils. Serpentine coils typically last two to three times longer than standard helical coils. As a result, it’s not uncommon for Enerquip’s serpentine coil heaters to last 30 years!

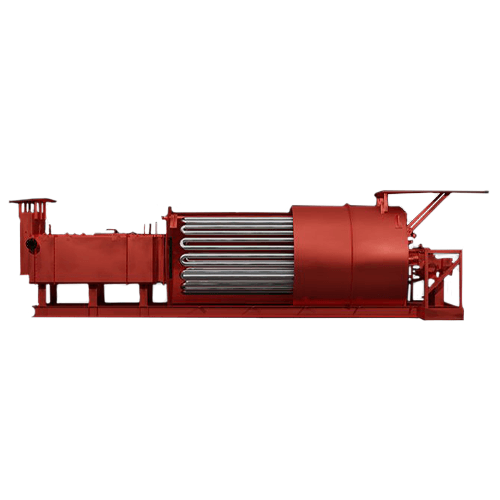

Easy Maintenance: For the rare times when maintenance is required, Enerquip’s serpentine coil can be removed, repaired or replaced, typically in less than one day.