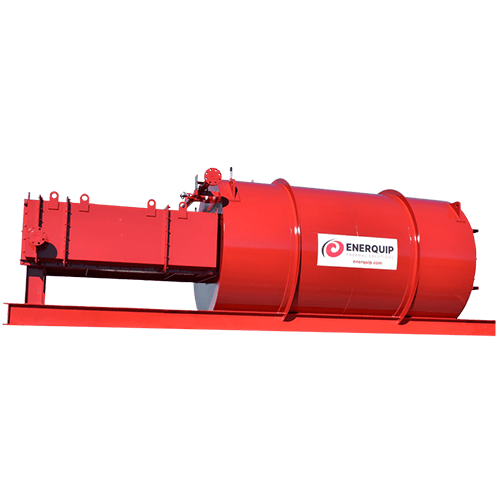

Description

Low NOx Heaters Industries Served

- Asphalt

- Biodiesel & Renewable Energy

- Food & Beverage

- Cannabis

- Chemical

- Commercial

- Dairy

- Personal & Pet Care

- Pharmaceutical

- Refining

- Tank Terminal

Our serpentine coils, and the space between them, offer a large combustion volume in the radiant section of our heater. This large combustion volume becomes an advantage for low NOx because it reduces the volumetric heat release as well as the overall fire box temperature, thereby reducing NOx formation.

The convection section of the Enerquip heater is designed to reduce the gas temperature leaving this section to 100ºF. above the incoming hot oil temperature. The lower the gas temperature (with the flue gas recirculation design) to the burner, the less NOx is formed during combustion.

The Enerquip design has the stack at the opposite end of the burner. There is relatively long run of flue gas recirculation duct required. We oversize this duct and, in most cases, will use a 10-inch diameter duct. This duct will be uninsulated. The large surface area of duct will quickly allow the flue gas to give up heat and reduce the gas temperature even further at the entrance to the burner. This reduced temperature will, again, allow for less NOx formation.

Enerquip has thermal fluid heaters in service with NOx levels of less than 9 PPM total NOx, and less than 50 PPM Co. We believe using flue gas recirculation is the most efficient way to achieve the lowest NOx level, but we also use burner models that can achieve 9PPM NOx without a flue gas duct.