Description

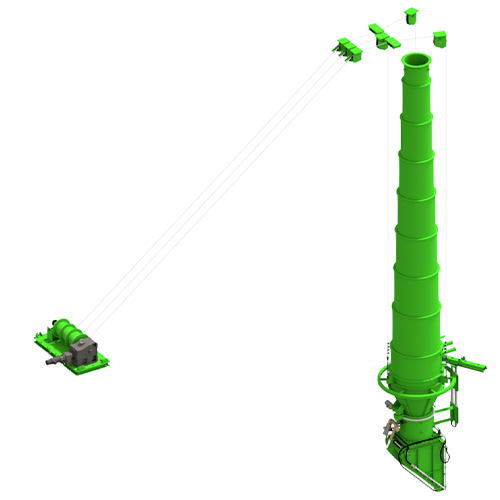

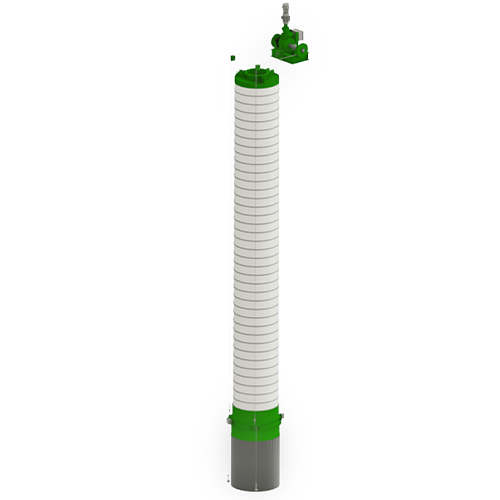

PEBCO® Telescopic Chutes are ideal for outdoor stockpiling or ship loading for their ability to contain product during freefall and accommodate a variety of application sizes and flow rates.

- Typically used for outdoor stockpiling of material or to load ships or barges

- Contains product during freefall from conveyor to pile, minimizing wind-blown dust

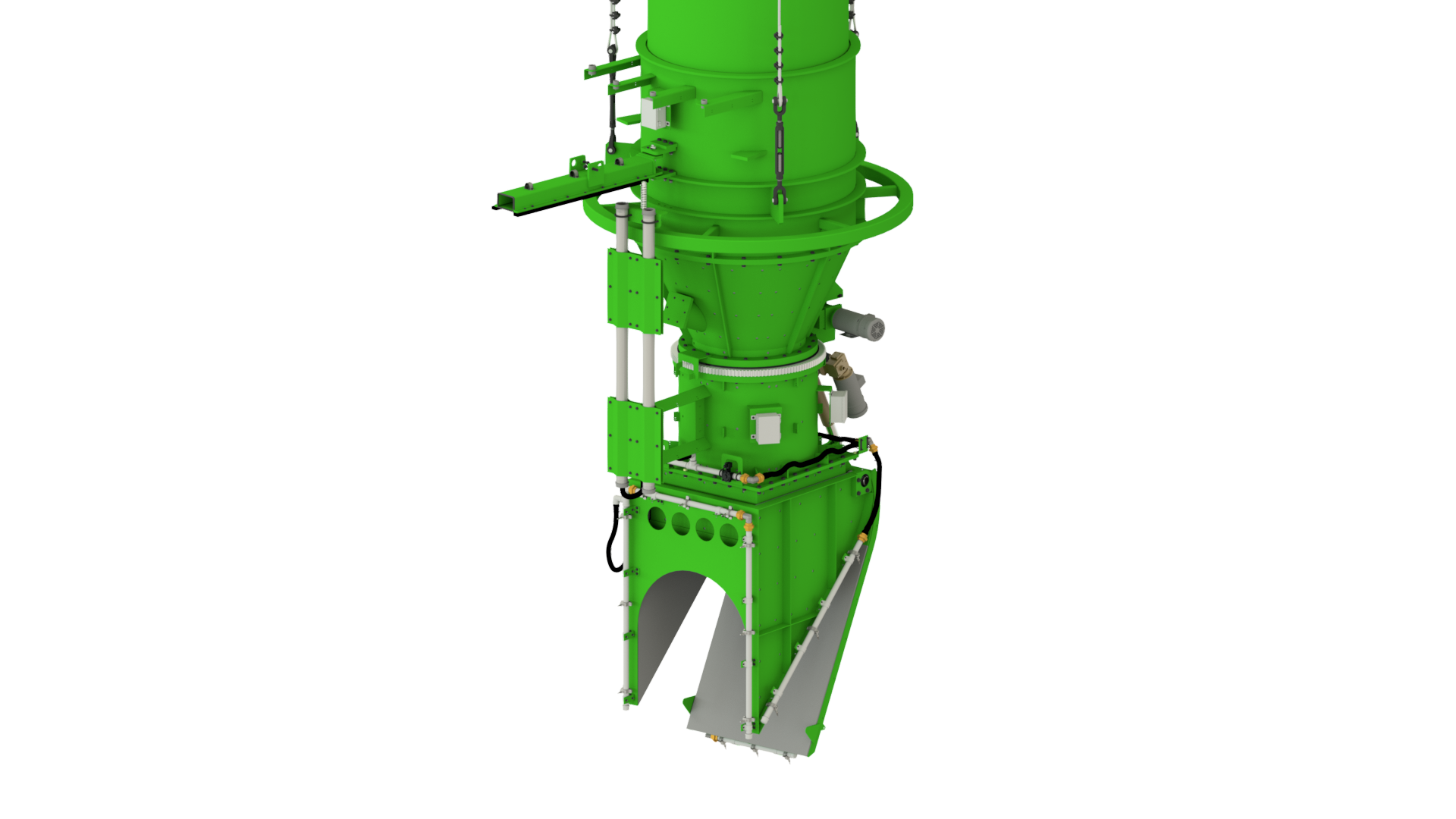

- Construction can be in any number of sections, diameters, or lengths to accommodate a variety of applications and huge range of flow rates

- Usual construction is carbon steel, abrasion resistant steel, and stainless

- Loose running clearances prevent binding of tubes due to material buildup

- Heavy rings on both ends reinforce each end of the tube and insure concentricity

- Tube diameters increase down the chute eliminating the possibility of plugging

- Tivar® tubes are available where weight or sticky products are a concern

Options

- Tube-to-tube seals reduce dusting, particularly with Tivar®

- Drop-in inlet tube liner can dramatically increase chute life

- Trimming spoons distribute material radially from centerline

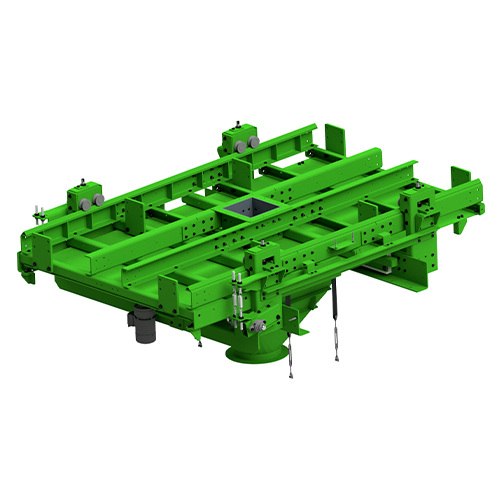

- Gimbals allow the chute to pivot when used on elevating conveyor booms

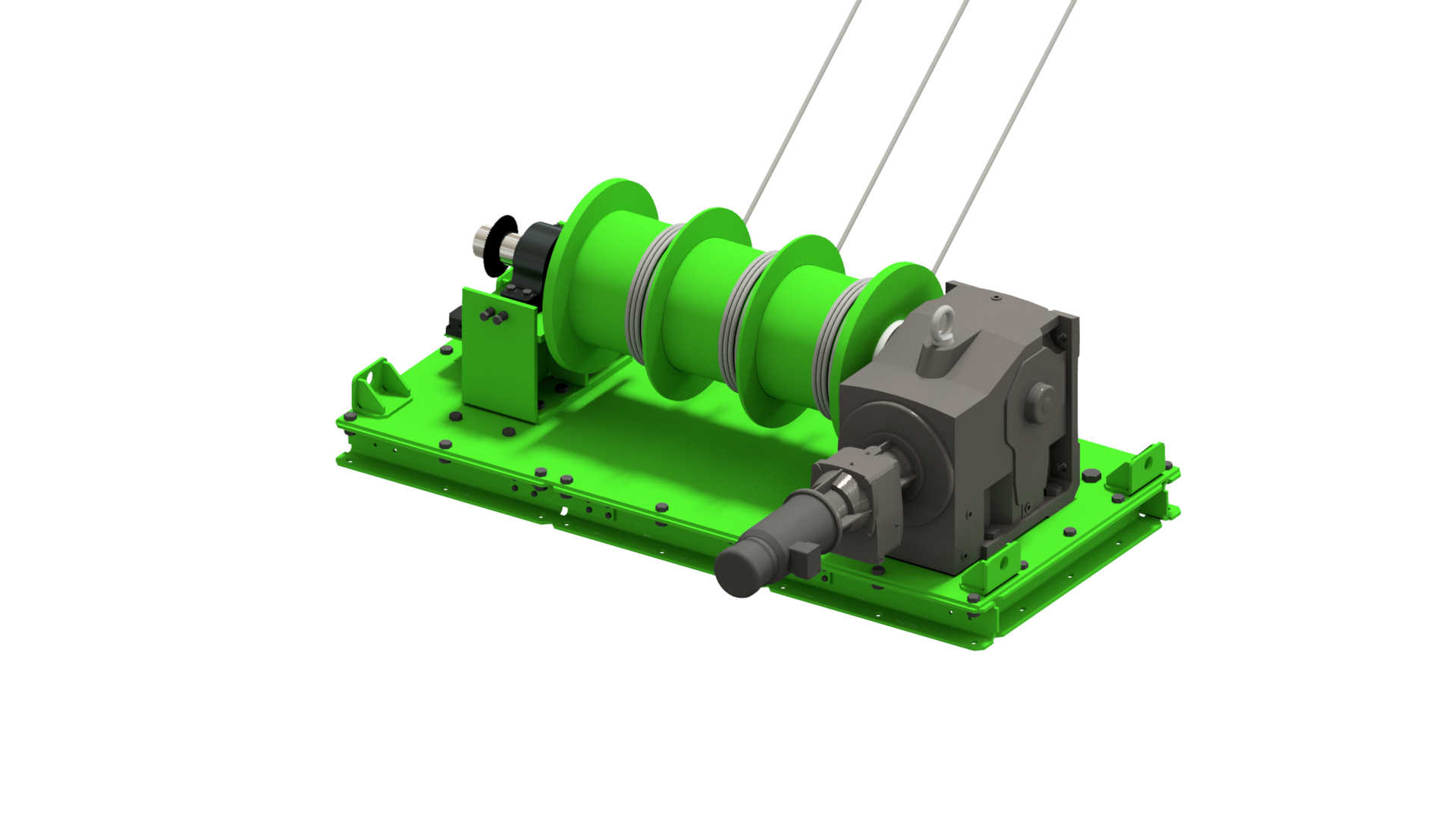

- Remote mount or integral winches include electrically released, mechanically applied brake

- Spray rings provide large volumes of water to reduce dust at the pile

- Fog spray headers by The Raring Corp encapsulate dust at the pile

- End of travel, ultimate-up, and slack cable limit switches provide feedback

- Tilt probe(s) sense material at the chute outlet

- Plugged chute sensors protect the system

- Auto-Raise and Auto-Lower control panels

- Controls