Description

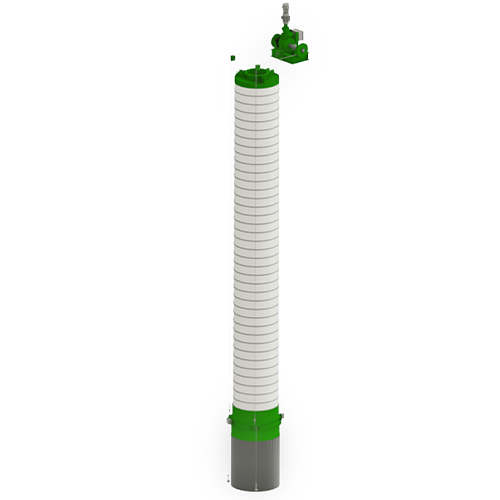

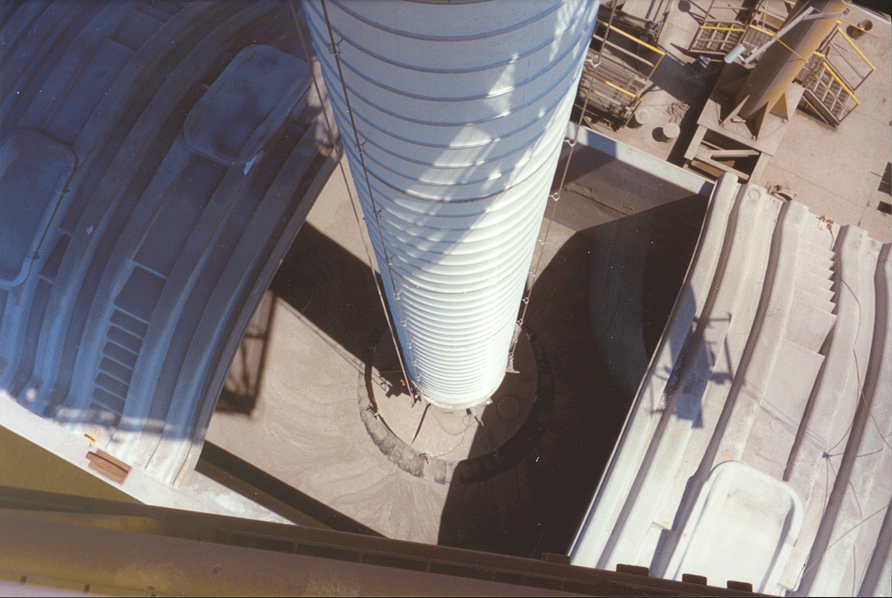

The PEBCO Cascade Chute® offers a permanent solution to degradation, segregation, and dust control by removing the ability for materials to freefall. The PEBCO Cascade Chute® can handle material flow rates up to 5000 tons per hour and lengths up to and exceeding 100 feet.

- Common uses include ship and barge loading as well as stockpiling material

- The solution to degradation, segregation, and dust control

- Oppositely inclined cones control material velocity from inlet to outlet, no material freefall

- Eliminates the need for dust collection at the discharge

- Typical construction features include:

- Fiberglass cones with bolted in wear liner

- Nylon or polyester cone straps

- All stainless connecting hardware

- Corrosion resistant construction is ideal for port environments

- Flow rates of 200-5000 TPH are attainable with most materials

- Extended lengths to 100 feet and more if needed

Options

- Outer shroud around the cone stack prevents wind-blow dust in outdoor applications

- Standard discharge skirt designs minimize dusting at the pile

- Custom skirt designs for fine powders are exceptionally effective at eliminating dust

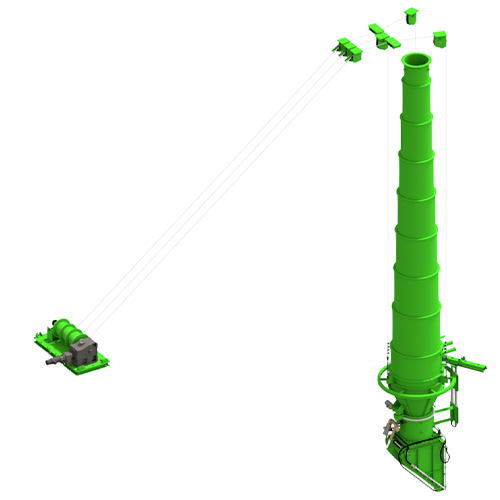

- Remote mount or integral winches include electrically released, mechanically applied brake

- Load cell system to monitor strap load. Detects overload condition or broken strap

- Gimbals allow the chute to pivot when used on elevating conveyor booms

- End of travel, ultimate-up, and slack cable limit switches provide feedback

- Tilt probe(s) sense material at the chute outlet

- Plugged chute sensors protect the system

- Transporter provides easier maintenance access

- Various cone materials and liners are available for your application

- Controls