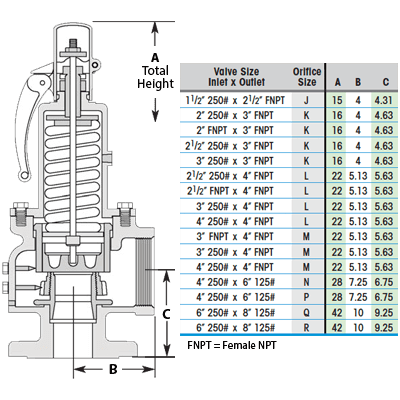

Description

How SVI Safety Valves Work

In the event steam pressure increases to the set point, the safety valve will “pop open” discharging steam faster than it can be produced. This allows system pressure to return to safe levels at which point the valve will close.

Note:

- Ratings are 90% of actual capacity.

- For Set Pressures over 250 PSIG, Consult factory

- For other sized, consult factory

- ASME Section I – Steam Boilers – pounds of saturated steam per hour @ 3% or 2 PSIG accumulation (whichever is greater)

- ASME Section VIII – Pressure Vessels – pounds of saturated steam per hour @ 10 % or 3 PSIG accumulation (whichever is greater)

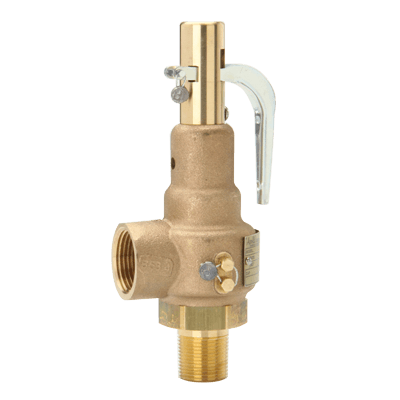

Safety valves shall be high capacity design with cast iron construction featuring rust-proof stainless steel stems, springs, washers and metal-to-metal lapped seats. Units shall be qualified to the ASME Boiler Code Section VIII and suitable for steam service.