Description

Steam Accumulators Applications

- Food / Beverage

- Pharmaceutical

- Steel / Chemical / Petrochemical

- Plastics / Rubber / Foam Manufacturing

Customers may not know the solution to severe boiler cycling, when their steam system requires very large quantities of steam in a short period of time. Problems occur when large boiler load swings are causing operating problems (i.e. the boiler shuts off because it doesn’t think it can meet the steam demand)

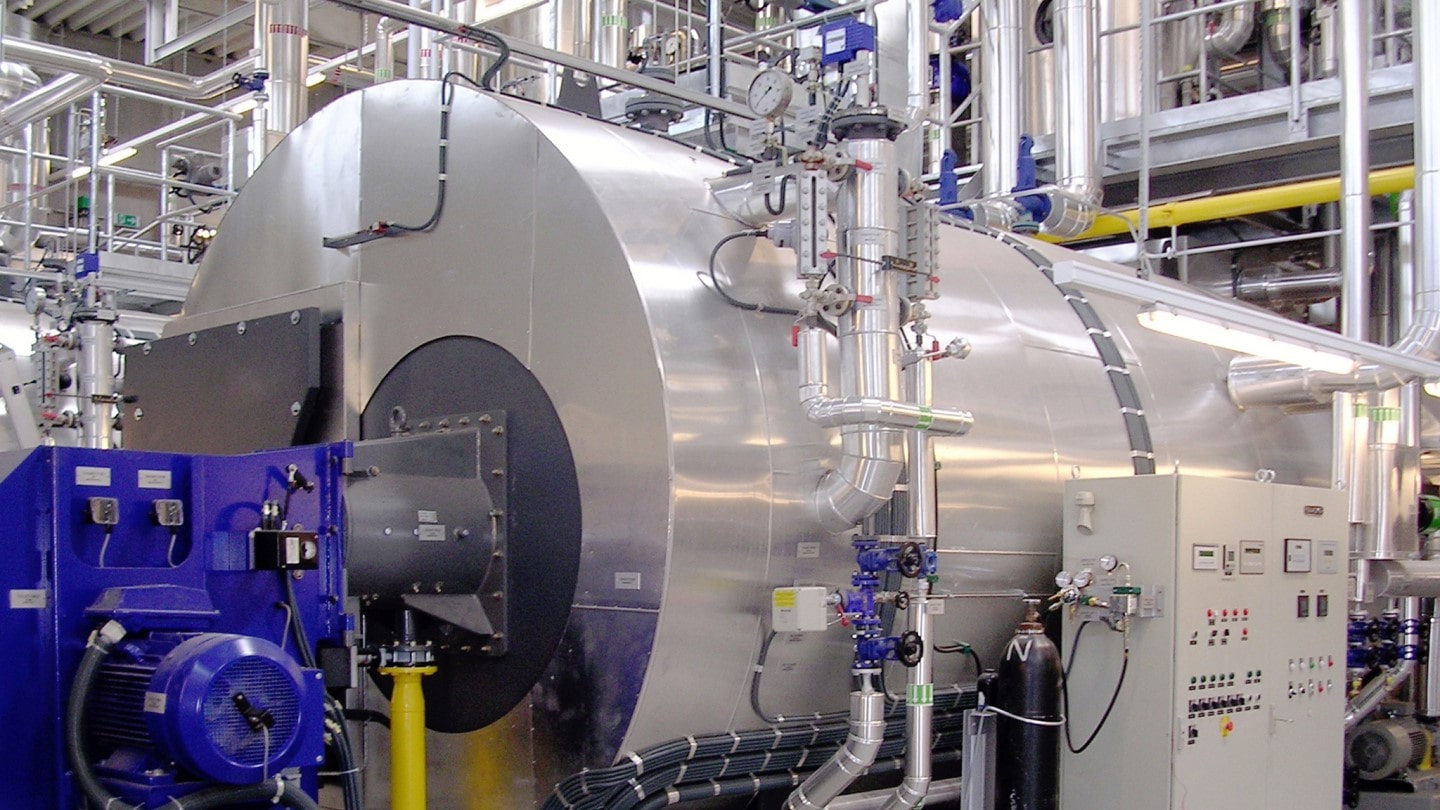

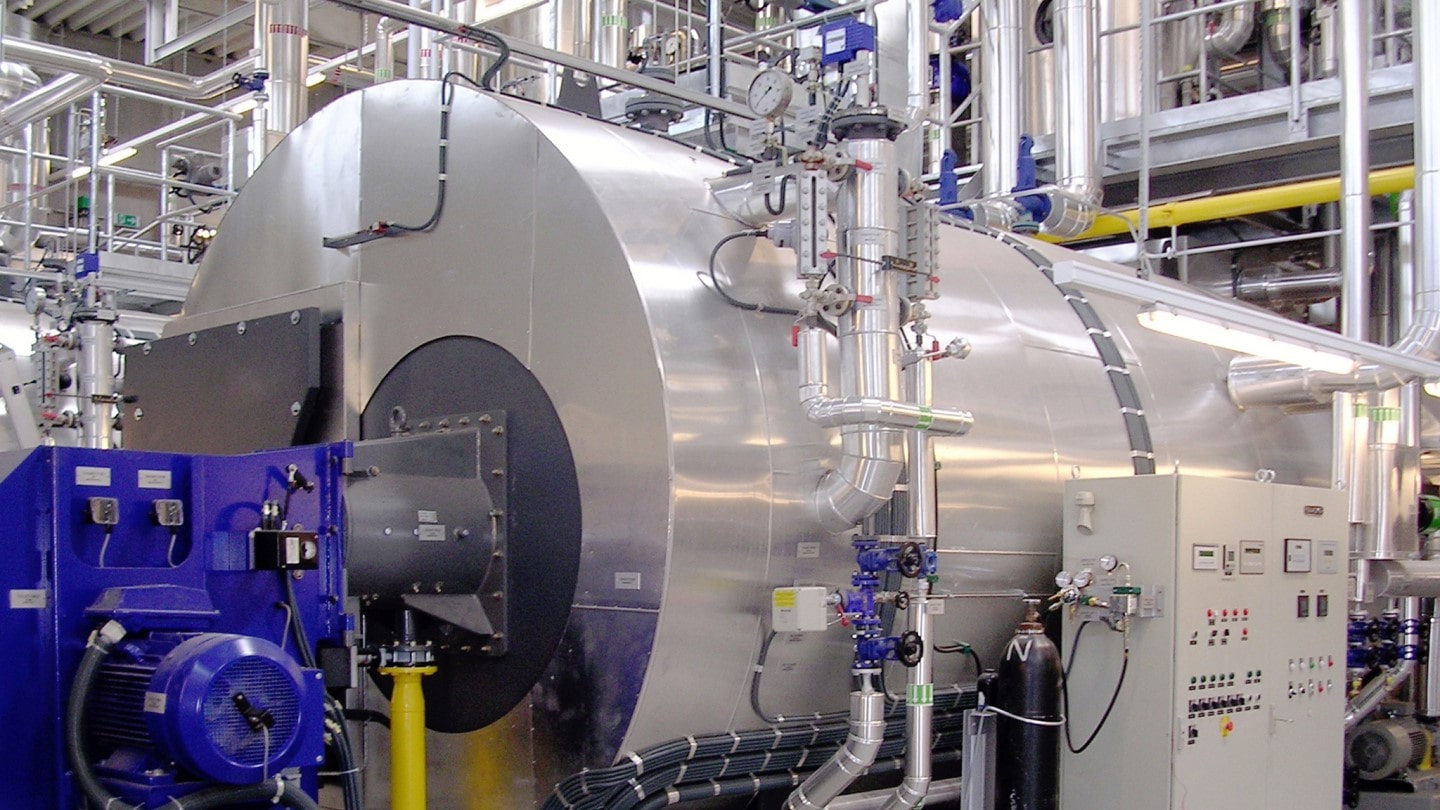

A steam accumulator is a pressure vessel (or tank) with internals and controls, that can reduce the fuel consumption, maintenance costs and increase the service life of your boiler by stabilizing the steam draw conditions (but it cannot make up for shortcomings in total boiler capacity). The accumulator acts as a flywheel or capacitor, storing energy for short periods until the process requires it. This is one of Cannon’s many products that help companies reduce overall energy consumption.

Large load swings frequently cause boilers to shut down because the system thinks it won’t be able to meet short term steam demands. When this happens, personnel must get involved to rectify the disruption in operations which leads to higher maintenance costs. By incorporating a Steam Accumulator, you can ensure smooth boiler operations with lower maintenance costs.