Description

How it Works

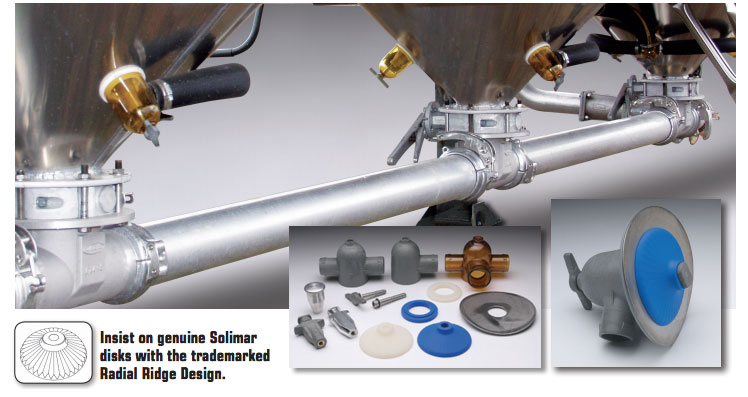

Pressurized air enters the exterior manifold & is forced through the opening of the tank’s hopper wall. The Fluidizer disk disperses the air along the inside of the hopper. Near the end of the unloading cycle the Fluidizer begins to vibrate. This combination of air flow along the hopper wall & gentle vibration of the disk prevents bridging & ratholing while generating quick product flow to the outlet & ensuring good cleanout of the trailer.

Fits Most Hopper Styles

Solimar’s Fluidizer Disks can be used on a variety of hopper styles & will conform to any hopper shape, curved or flat. One, two or three port manifolds available for various installation combinations.