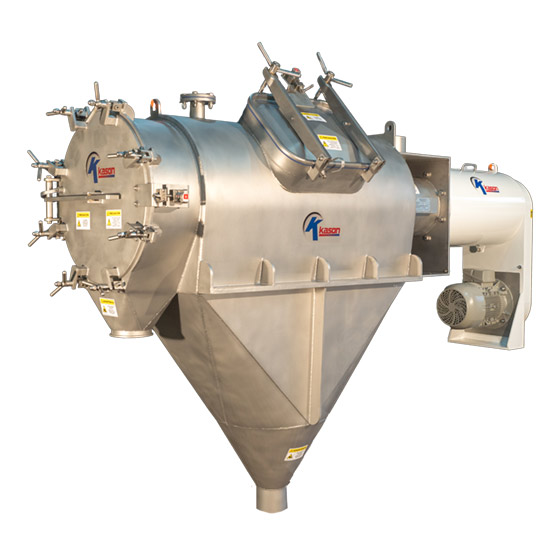

Quick-Clean Centrifugal Sifters and Separators

Quick-Clean Centrifugal Sifters

The CENTRI-SIFTER® centrifugal sifter features a hinged end cover and three-bearing shaft that cantilevers for quick removal of internal components.

External roller bearings are located at the motor end of the shaft and on a hinged cover at the discharge end for maximum support and vibration-free operation. When the end cover is hinged open, the shaft becomes a cantilever supported by a third externally-mounted roller bearing located between the motor-end bearing and material feed point, allowing internal components to slide freely from the opposite shaft end.

The sifter is ideal for food, dairy and pharmaceutical applications requiring thorough wash-down, as well as general chemical applications involving frequent screen changes/inspections or runs of multiple materials with no cross-contamination.

Dry or moist bulk solid material is gravity-fed into the feed inlet and redirected into the cylindrical sifting chamber by means of a feed screw. In addition to sifting, scalping, and dedusting of dry bulk materials, the screener can break up soft agglomerates and/or dewater moist solids or slurries.